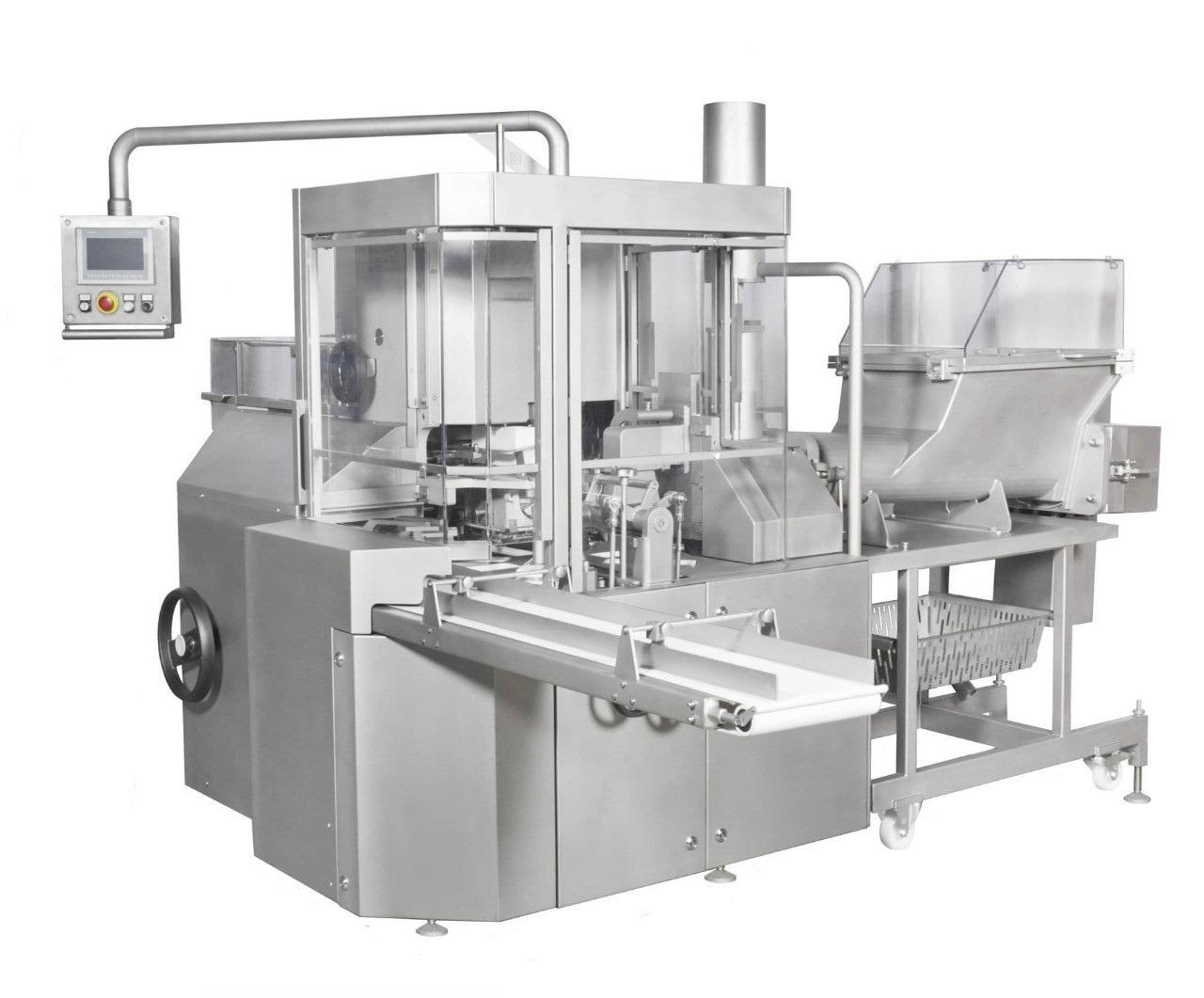

IPAC-2L - Automatic Packaging Machine for Bags

IPAC-2L

4-in-1 Packaging Machine for Plastic Bags with Reinforced Corner Cushion

The IPAC-2L is an industrial machine designed to automatically fill, weigh, and package products into bags or pouches, ensuring precise quantities. It is used in the agrochemical and food processing industries to package various types of products. This latest-generation mechanical packaging solution stands out thanks to its optimized design: four structured corners are added to the vertical pouches, providing a more aesthetically pleasing appearance, improved stability, and a strong visual impact on the shelf.

Type: Automatic bagging machine FILL SEAL 1 head

Application: Liquid food and agrochemical products

Advantage: Aesthetically pleasing, sturdy bags with a strong visual impact

Main features of the IPAC-2L

- 4-in-1 packaging machine: bag forming, automatic filling, welding/sealing and counting

- Plastic bags with reinforced corner cushions for better stability and aesthetics

- Production speed: 30 to 35 cycles/minute (2100 sachets/hour)

- All parts in contact with the product are made of 316L stainless steel

- Structure and components made of 304L stainless steel for robustness

- Simple interface for quick and ergonomic use

- Efficient pneumatic system and reliable, quiet film pulling mechanism

- Washable circuit in CIP without disassembly

- Compatible with different types and sizes of bags

Areas of application

Food processing industry: Milk and yogurt, milk, juices and beverages.

Agrochemical industry: Chemicals suitable for liquid packaging.

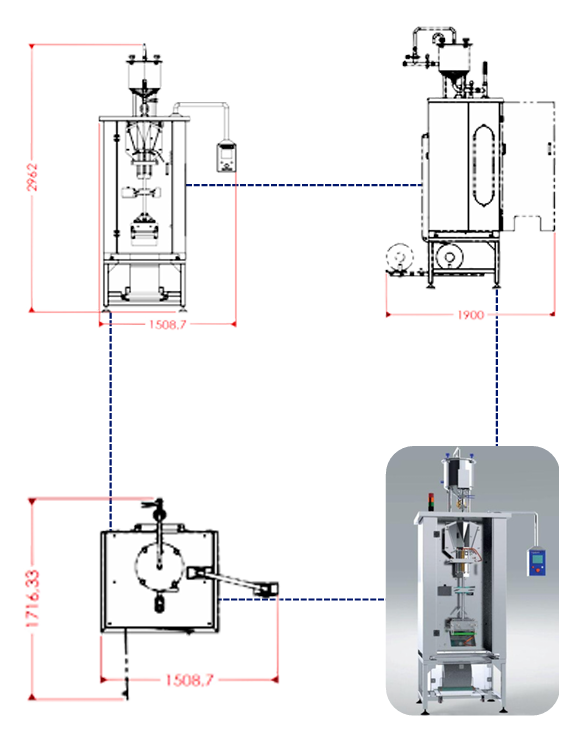

Installation plan

Technical installation diagram of the IPAC-2L machine - Dimensions and connections

IPAC-2L Technical Data

| Setting | Specifications |

|---|---|

| Model | IPAC-2L (FILL SEAL 1 HEAD) |

| Products suitable | Milk and yogurt, milk, juice and drinks |

| Weight/Volume | Adjustable from 100 to 500 ml |

| Bag dimensions | Width 150 mm / length depending on volume |

| Speed | 30 to 35 cycles/minute |

| Production capacity | 2100 sachets/hour |

| Plastic width | 320 mm (± 2 mm) |

| Plastic thickness | 70 to 90 microns |

| Film materials | LDPE |

| building materials | 316L stainless steel (product contact) / 304L stainless steel (structure) |

| Product pressure | Maximum inlet pressure: 0.5 bar / Maximum CIP pressure: 1.5 bar |

| Cleaning | Washable circuit in CIP without disassembly |

| Film reel diameter | 300 mm |

| Dimensions (L×W×H) | 900×800×2960 mm |

| Power | 0.75 kW |

| Pneumatic supply | General supply pressure: 6 bar |

| Tension | 220 V AC Single Phase |

| Certifications | Made in Morocco NM/CE |

Advanced features and equipment

| Standard equipment | Technical specifications |

|---|---|

| Impulse welding system | With precise temperature control |

| Control via API/Automation | Intuitive touchscreen control |

| Dose counter | Integrated cruise control |

| Electrical cabinet | Protected and compliant with standards |

| Exit chute | For the organized disposal of the bags |

| Floating system | Automatic level control |

| Film disinfection | By integrated UV radiation |

Competitive advantages

- Emballage rapide et continu : Production automatisée sans interruption

- Pesage automatique et précis : Respect strict des quantités spécifiées

- Réduction des coûts : Diminution significative de la main-d'œuvre requise

- Amélioration qualité : Emballage uniforme et professionnel

- Polyvalence : Compatible avec différents types et formats de sacs

- Traçabilité : Système de comptage intégré pour suivi de production

- Impact visuel : Sachets esthétiques à coins renforcés pour meilleure présentation

Applications par secteur

Agroalimentaire

- Lait et produits laitiers

- Yaourts liquides et Leben

- Jus de fruits naturels

- Boissons diverses

- Sauces et condiments liquides

Agrochimique

- Engrais liquides

- Produits phytosanitaires

- Solutions nutritives

- Additifs agricoles

- Produits de traitement

Bénéfices opérationnels

L'IPAC-2L transforme votre ligne de conditionnement avec une efficacité optimale : automatisation complète du processus, réduction des erreurs manuelles, augmentation de la productivité, et emballage de qualité supérieure qui valorise vos produits sur le marché.

Frequently Asked Questions about IPAC-2L Technical Issues

Improve production

Explore compatible machines

Complete your production line with our range of automated packaging solutions.

Learn moreOther products in this section

Hello! Click below to chat with our team on WhatsApp.