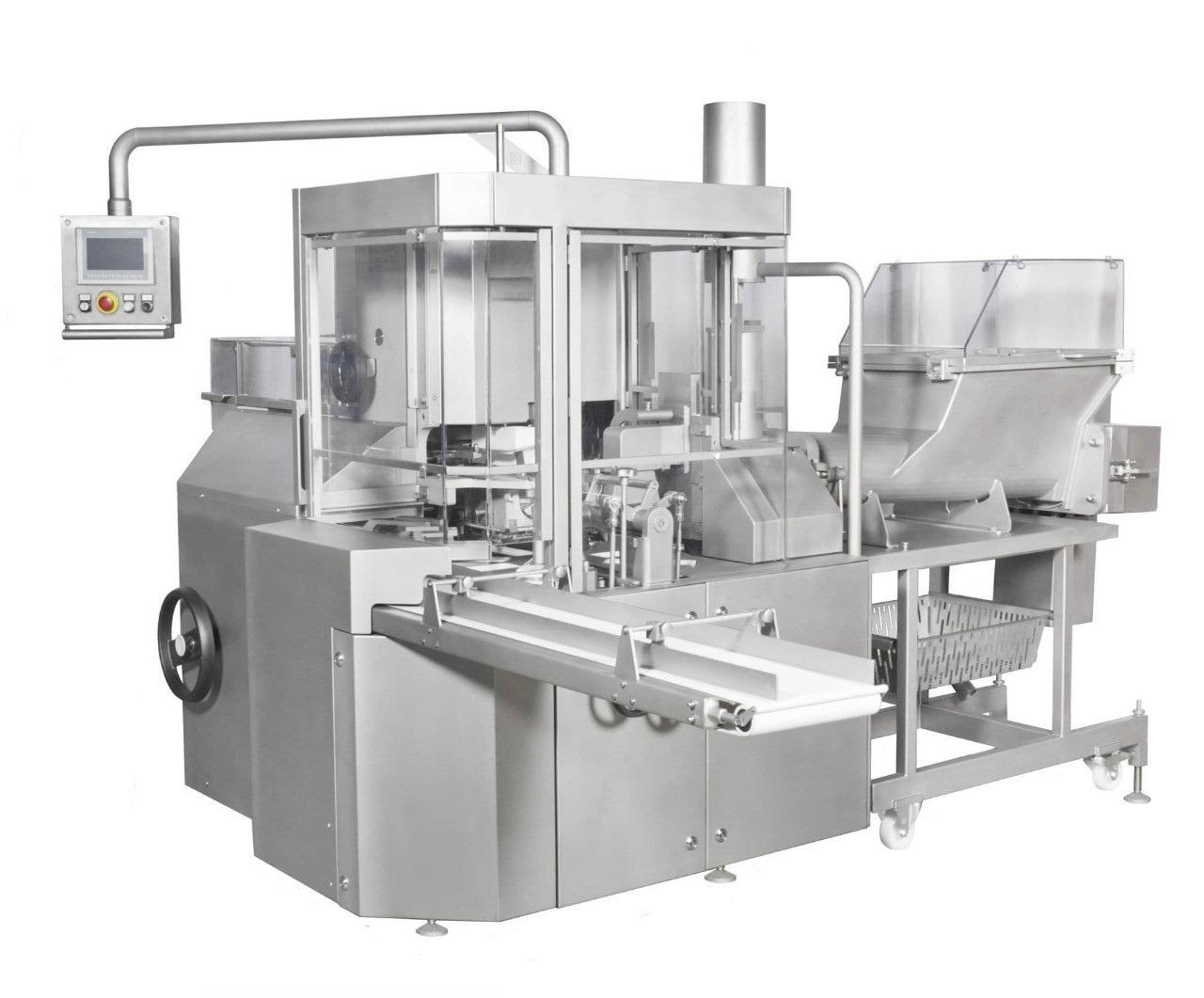

Fill Seal 2500 - Compact Automatic Filling and Sealing Machine

Filling Sealing Gasket 2500

Compact and versatile filling and sealing machine

The Fill Seal 2500 is a compact and versatile rotary table filling and sealing machine designed for ease of use and flexibility in handling cups made of different materials. It is suitable for packaging a wide variety of food products at a rate of up to 2,500 units per hour.

Type: Rotary filling and sealing

Format : Compact and versatile

Specialty: High-performance sealing gasket

Main features

The Fill Seal 2500 model stands out for its adaptability and efficiency in packaging various food products. Its rotating table and customizable structure allow it to adapt to a wide range of applications, from dairy products to sauces and dressings.

The machine offers various packaging methods, including sealing, gas injection, MAP/ATP, and vacuum, to meet diverse preservation needs. Available in different sizes (standard, large, and XL), it adapts to various production scales, making it a versatile choice for businesses of all sizes.

The Fill Seal 2500 combines high production capacity with user-friendly operation, making it an ideal solution for medium-sized businesses looking for a reliable and efficient filling and sealing machine to meet their diverse packaging requirements.

Sealing

Gas rinsing

MAP/ATP

empty

Applications

Ideal for filling and sealing a wide variety of food products: dairy products, yogurts, sauces, dressings, condiments, liquid and semi-liquid products, requiring quality sealed packaging.

Technical data

| Model | Fill Seal 2500 | Fill Seal 2500 Large | Fill Seal 2500 XL |

|---|---|---|---|

| Dimensions (L x l x H) | 209 x 115 x 196 cm | 240 x 127 x 195 cm | 189/205 x 207 x 232 cm |

| Weight | ~600 kg | ~900 kg | ~1050 kg |

| Electrical power (Cover) | 3 kW | 3.5 kW | 5.5 kW |

| Electrical Power (Film) | 3 kW | 3.5 (N) - 4.5 (VG) kW | 5 (N) - 6 (VG) kW |

| Pots per cycle | 1 | 1 | 1 |

| Ø Max Cups (Lid) | 125 mm | 150 mm | 200 mm |

| Ø Max Cups (Movie) | - | 150 mm (N) - 125 mm (VG) | 200 mm (N) - 180 mm (VG) |

| Maximum cup height | 130 mm | 130 mm | 180 mm |

| Maximum production capacity | Up to 2500 units/hour | ||

Advanced Features & Technologies

Touchscreen panel: It allows for easy adjustment of working parameters and quick access to saved recipes, improving operational efficiency and ease of use.

Modified atmosphere packaging (MAP): This function, unique for a rotary table machine, extends the shelf life of products by changing the atmosphere inside the packaging.

Available dosing options: The FS 2500 can be equipped with different dosing systems (volumetric, timed, drawer, flowmeter) for fast and precise filling, suitable for a wide range of products.

Entièrement lavable : La conception de la machine facilite le nettoyage, garantissant l'hygiène et la conformité aux normes de sécurité alimentaire.

Options & Accessoires

- Système de nettoyage ultra : Lampes UVC, lumière pulsée, peroxyde d'hydrogène.

- Hotte à flux laminaire : Air microfiltré pour augmenter la durée de conservation.

- Système de sertissage : Pour pots en verre ou céramique.

- Pick & Place : Automatisation de la mise en place des récipients.

- Imprimante à jet d'encre : Marquage des dates de péremption et lots.

- Stockage de grande capacité : Convoyeur d'alimentation pour autonomie maximale.

- Aspiration de matières étrangères : Élimine les corps étrangers du récipient.

- Système de nettoyage en place (CIP) : Lavage autonome de l'unité de dosage.

Méthodes d'emballage disponibles

- Scellement standard

- Rinçage au gaz

- Emballage sous atmosphère modifiée (MAP/ATP)

- Scellage sous vide

Vidéos de démonstration

Découvrez notre machine de remplissage et scellage Fill Seal 2500 en action à travers ces vidéos de démonstration.

Technical Frequently Asked Questions

Improve production

Explore compatible machines

Complete your production line with our range of automated packaging solutions.

Learn moreOther products in this section

Hello! Click below to chat with our team on WhatsApp.