Single pumps

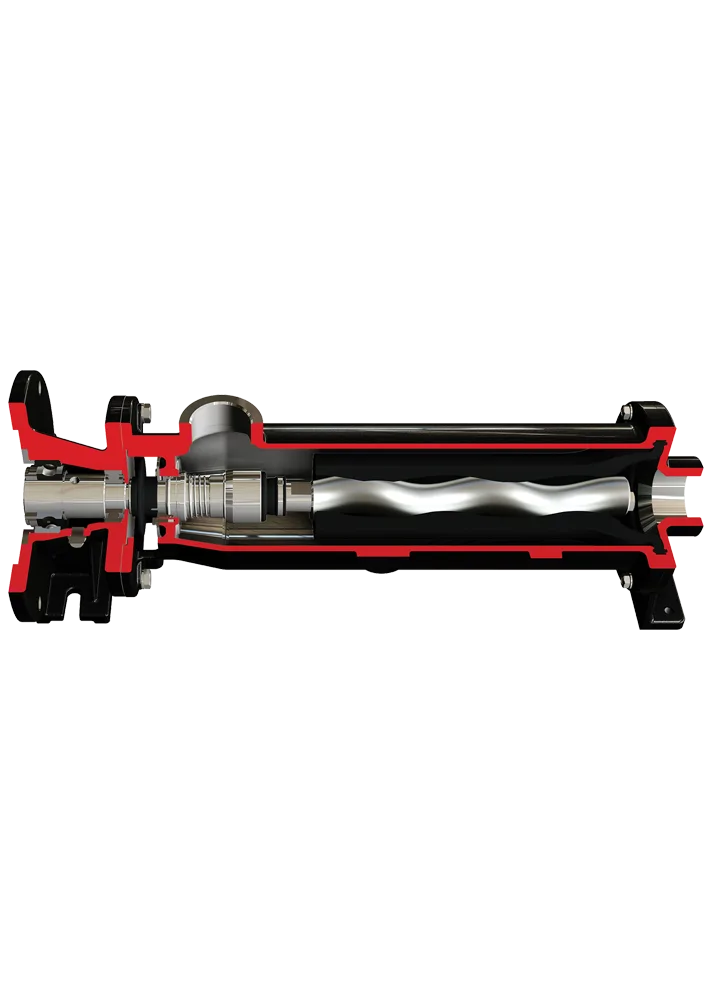

Positive displacement pumps for regular and linear flow

Monobloc pumps ensure a regular, linear, and measurable flow rate. Silent and vibration-free, they guarantee continuous flow and prevent turbulence. As a result, the viscosity of the fluid they contain remains unchanged.

Flow rate: Up to 300 m³/h

Pressure: Up to 72 bar

Temperature: From -30 °C to +300 °C

Main characteristics of single-unit pumps

- Various capacity options (max: 300 m³/h)

- Ability to work under high pressure (max: 72 bar)

- Wide temperature range (-30 °C to +300 °C)

- Suitable for transferring fluids with low and high viscosity

- Transfer of sensitive, sticky, abrasive, grinding and foaming fluids

- Regular, linear, fluctuating, and measurable flow rate

- Vibration-free and silent operation

- Material options: cast iron, 316 stainless steel and other special alloys

- Resistance to all types of wear and corrosion

- Compatibility with PLC/SCADA systems

- Compliance with CIP/SIP studies

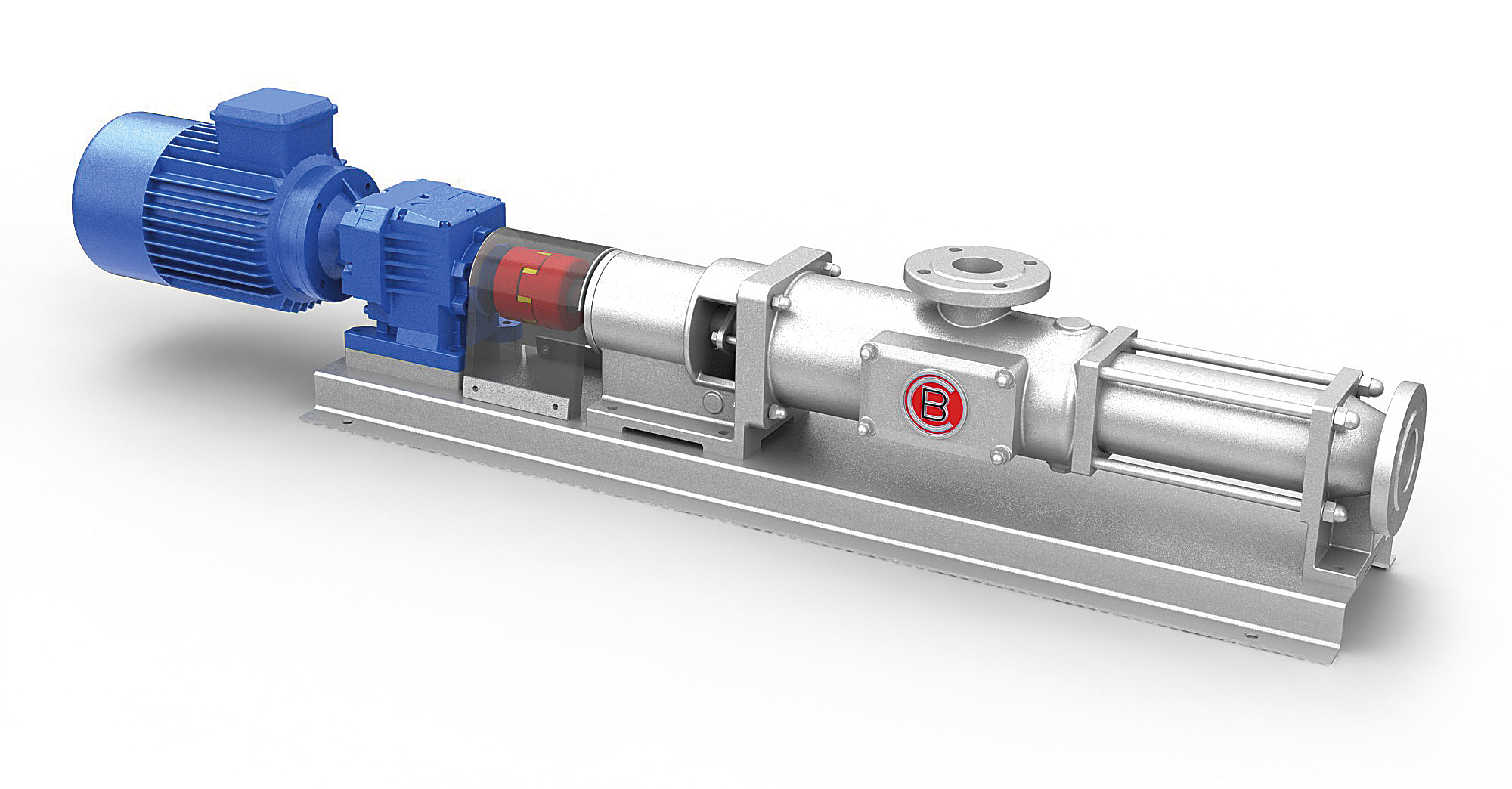

Nova Rotors industrial flanged range

The Nova Rotors flanged industrial range forms the basis of the Diamond range. With its robust cast stainless steel housings and large inspection ports, it is ideal for the most demanding applications. The Diamond DN and JN series represent the optimal solution for a wide range of industrial liquid pumping applications.

These models are synonymous with durability, reliability, performance, and versatility. They are available with UNI, DIN, and ANSI flanged connections, as well as GAS BSP threaded connections.

The drive system is connected directly to the pump via a flange. This extremely economical and compact solution significantly reduces installation costs and simplifies maintenance.

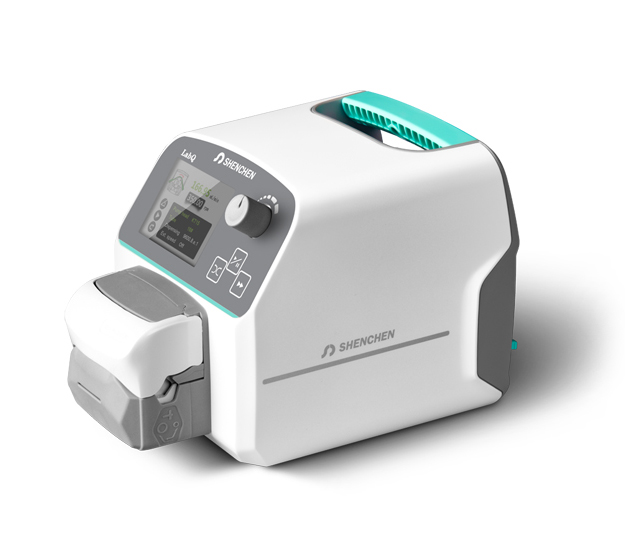

Nova Rotors Hygiene Range

Nova Rotors' advanced Hygiene range is ideal for the food, pharmaceutical, chemical, and cosmetic industries. Certified to EHEDG and 3A standards, these pumps guarantee maximum disinfection thanks to their fully hygienic design.

They are particularly effective for clean-in-place (CIP) and sterilization-in-place (SPS) procedures. The pump geometry is specifically designed to ensure complete drainage and eliminate dead zones.

Available series:

- DXO Series: Sanitary pump with open seal, stagnation-free design

- DXC Series: Sanitary pump with closed needle, ideal for abrasive applications

- JXO/JXC Series: Bearing and free-standing bare shaft for specific applications

Industrial application areas

Agrifood

Dairy products, animal feed production, honey processing, preserves, fruit pulp, jam, butter, hazelnut paste, beverage production, chocolate, syrup, sugar transfer, molasses and meat puree under hygienic conditions.

Petrochemical and Pharmaceutical

Transfer of phosphoric acid, liquid fuel, shampoo, lime, iron chloride, caustic soda, alum, and other aggressive chemicals. These industries require equipment capable of withstanding high temperatures and pressures.

Water purification

Transmission of chemical solutions such as polyelectrolytes, lime, and all types of treatment sludge in water and wastewater treatment, feeding of belt filter presses and filter press sludge.

Mining industry

Pumping of water containing solid materials such as clay, sand, etc. in the mining sector, disposal of bilge waste in the marine environment.

Various industries

Applications involving viscous liquids in the pharmaceutical, paper, ceramics, cosmetics and other industries requiring stable and reliable fluid transfer.

Environment

For wastewater treatment and sludge transfer, our single-stage pumps allow for the handling of fluids containing solid particles with optimal efficiency and minimal wear.

Technical advantages of single-unit pumps

• Regular, linear and measurable flow rate without fluctuations

• Quiet and vibration-free operation

• Transfer of low and high viscosity fluids

• Preservation of fluid fibers and product structure

• Continuous flow with self-vacuum (vacuum from 8.5 m)

• Resistance to wear and corrosion

• Transfer of abrasive, sticky and foam-prone fluids

• Compatibility with PLC/SCADA systems

• Compliance with CIP/SIP standards

• Does not alter the properties of the transferred product

Frequently Asked Questions

Fluid Transfer Products

Hello! Click below to chat with our team on WhatsApp.