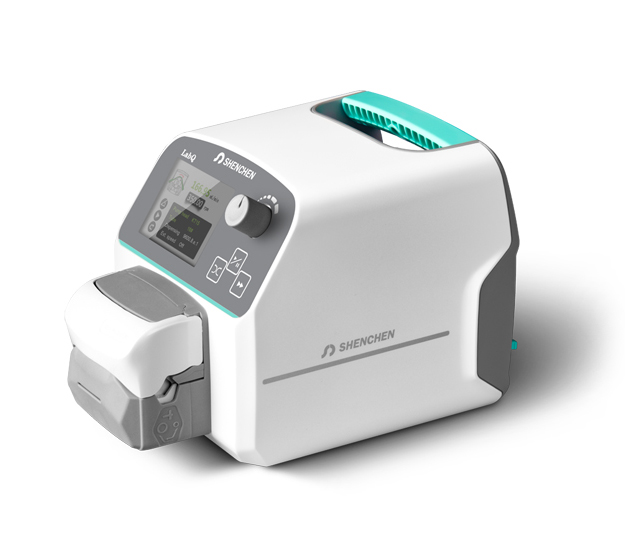

DORIS dosing pumps

Precision transfer devices for chemicals

Metering pumps are precision transfer devices designed for applications requiring the distribution of chemicals such as acid, chlorine, liquid fertilizers, etc., at specific flow rates.

Efficiency: Up to 30% energy savings

Maintenance: Ultra-low maintenance cost

Warranty: Five-year lifetime warranty on the membrane

Main features of DORIS dosing pumps

- High efficiency with up to 30% lower energy consumption

- Compact structure and small footprint

- PTFE valve seat for optimal sealing

- Pure PTFE membrane for long service life

- Pump head made of high modulus material with full chemical compatibility

- Standby mode enabled for extended use

- Simple and visual digital display for easy use

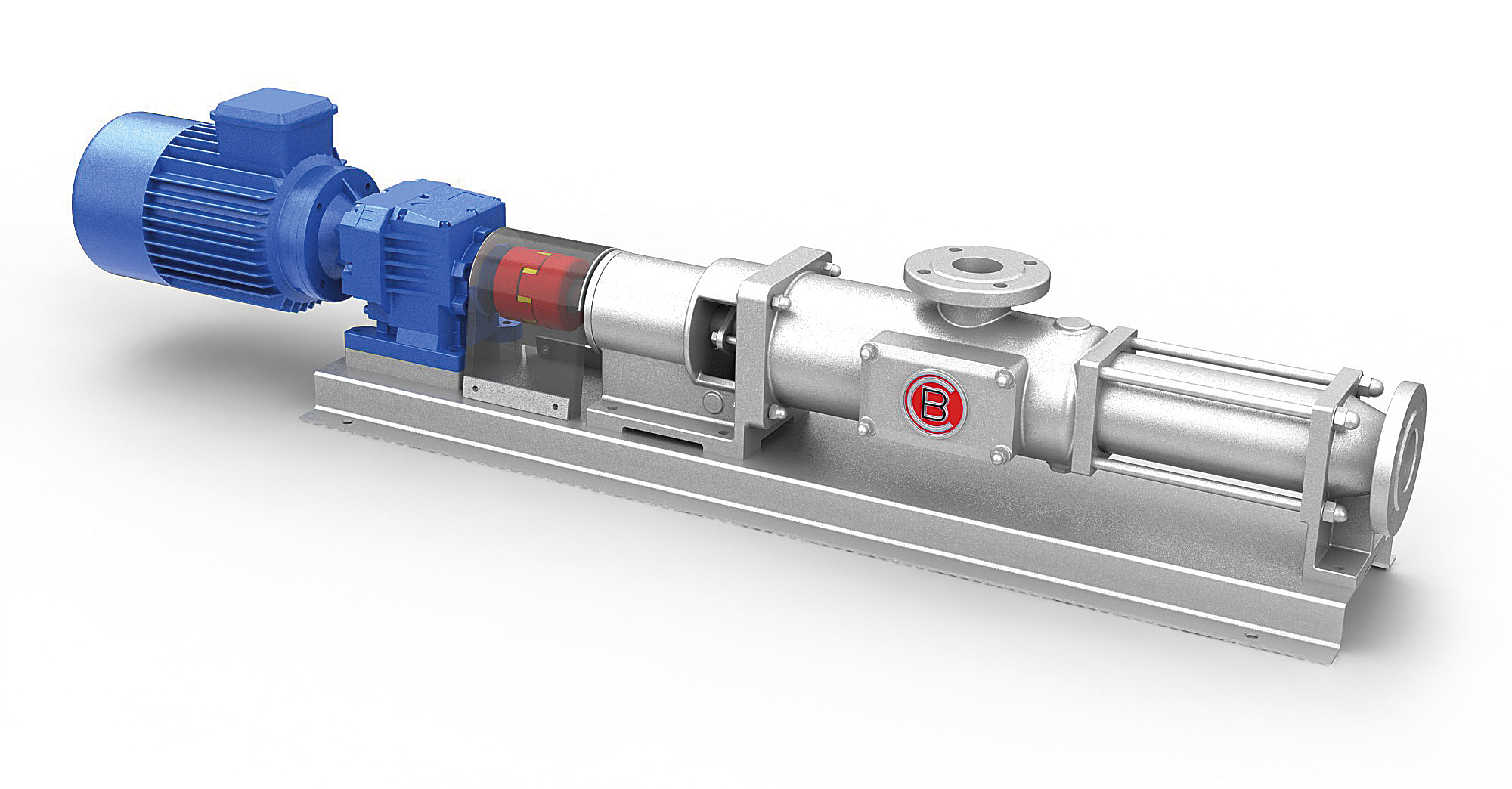

Technical advantages

Doris metering pumps offer consistent and reliable quality, superior performance, a simple and proven structural design, and a more powerful motor. They guarantee a stable flow rate while reducing the number of accessories, which significantly extends their service life, lowers maintenance costs, and ensures the stable operation of numerous dosing systems.

Thanks to our expertise in independent circuit R&D and our extensive experience in electromagnetic design, we achieve the same performance as similar products, with reduced energy consumption and minimal footprint.

Optimized structure

The pump head, made of high-modulus material, offers complete chemical compatibility. Its internal design has proven effective in preventing flashover and cavitation. It also optimizes fluid flow and reduces excessive shear forces. This helps maintain pump flow rate and increase overall efficiency.

Structural characteristics:

- PTFE valve seat with rubber O-ring

- Compact and streamlined structure

- Design that facilitates maintenance

- A solution that can be customized to your needs.

Industrial application areas

Agrifood

Hygiene, safety, and process efficiency are paramount in the food and beverage industry. Our easy-to-clean and hygienic stainless steel solutions ensure safe operation across a wide range of production lines, from dairy and beverages to fruit juice and beer production.

Automobile

In the automotive industry, temperature control and fluid management are essential in processes such as production lines, testing systems, and paint applications. Our compact and robust equipment ensures energy efficiency and operational continuity in these processes.

Marine

Marine applications demand equipment that can withstand extreme environmental conditions and has a long service life. Our saltwater-resistant, low-maintenance solutions reliably provide cooling, heating, and fluid control in ship systems.

HVAC

Efficiency and longevity are essential for air conditioning and domestic hot water systems. Our heating, cooling, ventilation, and domestic hot water solutions optimize energy savings and system performance in the building sector.

Petrochemical and Pharmaceutical

These industries require equipment capable of withstanding high temperatures and pressures. They also require system solutions that can handle corrosive and aggressive gases and liquids. We offer robust structures that meet these requirements, thus ensuring process safety and continuity.

Metallurgical industry

Systems subjected to high temperatures and pressures during metalworking processes require durable and long-lasting solutions. Our products, which guarantee reliability and process stability on industrial production lines, optimize productivity.

Energy

Efficiency is crucial for power generation, cogeneration, and heat recovery systems. Our high-performance solutions help reduce energy costs while ensuring the sustainable operation of these systems.

Textile

Temperature control and energy efficiency are essential in processes such as printing, dyeing, finishing, and drying. Our solutions, specifically designed for textile production processes, improve operational efficiency and optimize energy consumption.

Advantages of DORIS dosing pumps

• High efficiency with energy savings of up to 30%

• Compact structure and small footprint

• Ultra-low maintenance cost

• Pure PTFE membrane with a five-year lifetime warranty

• Standby operation allowed

• Simple digital display and easy setup

• A solution that can be customized to meet your needs

• Stable flow rate and reliable performance

• Robust design for demanding applications

• Total chemical compatibility

Frequently Asked Questions

Fluid Transfer Products

Hello! Click below to chat with our team on WhatsApp.