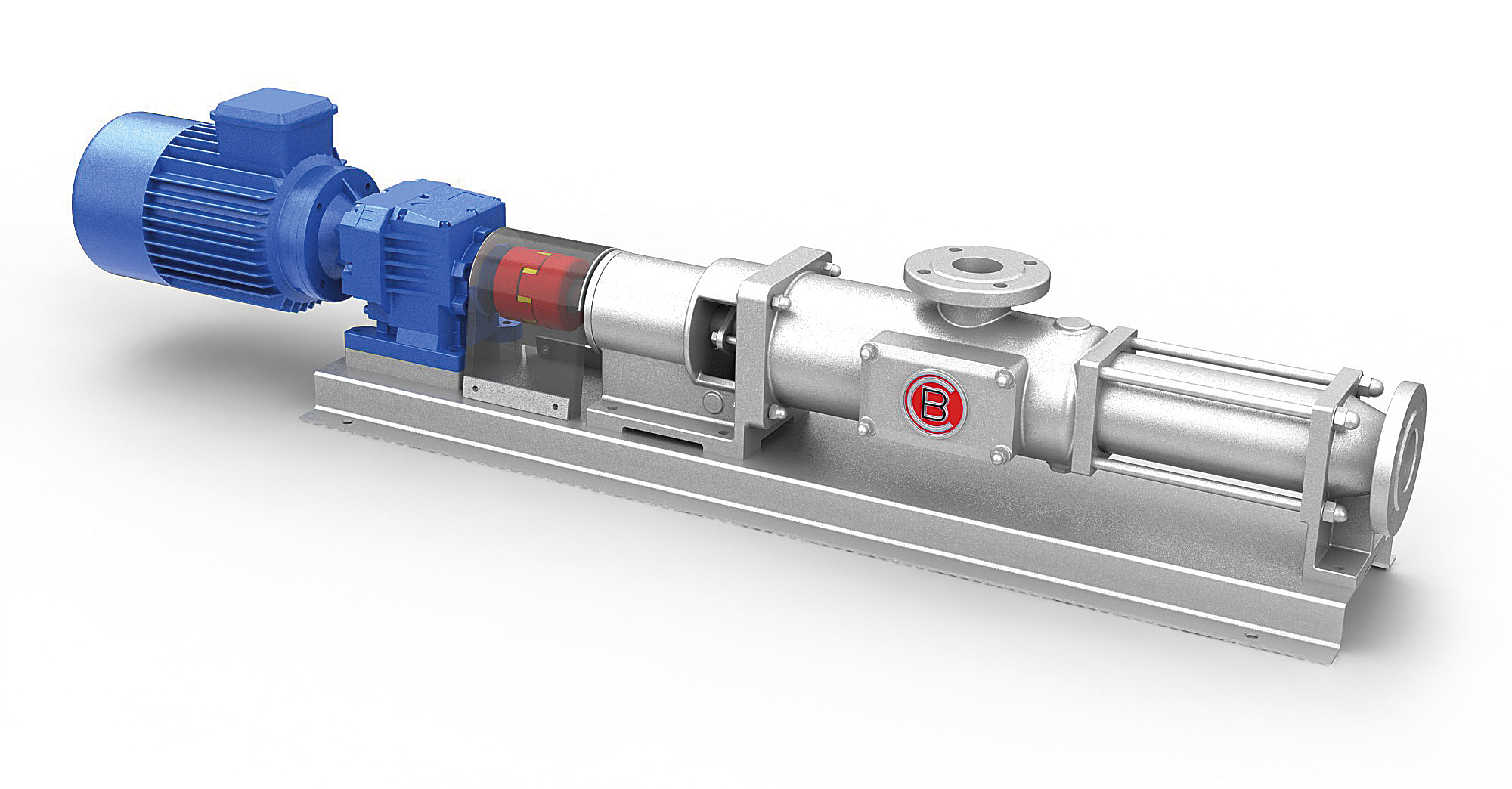

Eccentric Screw Pumps

Progressive cavity pumps for sensitive and high-viscosity products

PCP Series eccentric screw pumps offer gentle and consistent transfer of viscous, pasty, or lumpy products. Their progressive cavity design ensures non-pulsating flow that preserves product integrity, making them ideal for food, cosmetic, and chemical applications.

Flow rate: 0.1 to 200 m³/h

Pressure: Up to 48 bar

Viscosity: Up to 2,000,000 cP

Main characteristics of eccentric screw pumps

- Progressive cavity principle for smooth, non-pulsating flow

- Rotor made of treated stainless steel and stator made of food-grade elastomer

- Flow rate proportional to rotational speed for precise control

- Self-priming and reversible operating capability

- Low shearing of products, preservation of particles and fibers

- Compliant with FDA, EC1935/2004, and 3A Sanitary Standards

- ATEX and EHEDG certifications for sensitive environments

Operating principle

Eccentric screw pumps operate on the progressive cavity principle. An eccentric metal rotor rotates inside an elastomer stator, creating sealed cavities that progress from suction to discharge. This movement allows for a constant and smooth transfer of the product without pulsation or shearing.

The flow rate is directly proportional to the rotational speed, providing precise flow control. The unique design allows the transfer of highly viscous, abrasive products, or products containing solid particles, while preserving their structural integrity.

Advanced features

Technical advantages

• Constant, non-pulsed flow rate

• Low shear of products

• Self-priming up to 8.5m

• Limited dry running

• Easy and quick maintenance

• High volumetric efficiency

Available options

• Electronic speed controller

• Double-sealed mechanical cartridge

• Integrated CIP/SIP cleaning system

• Pressure and temperature sensors

• Stator/rotor replacement kits

• Aseptic and hygienic version

Available configurations

Standard industrial version: For abrasive products and general applications

Food-grade hygienic version: With Ra ≤ 0.8µm finish and smooth surfaces

Aseptic version: With tri-clamp fittings and dead zone-free design

Lubricated version: For dry or particularly abrasive products

Twin-shaft version: For highly viscous products and high-pressure applications

Operating pressure: Up to 48 bar depending on configuration

Maximum temperature: Up to 140°C depending on the materials

Industrial application areas

Food Industry

Gentle transfer of fruit purees, tomato paste, processed cheese, sauces, and pasta. Preserves the pieces and texture of delicate products without altering their organoleptic qualities.

Cosmetics and Perfumery

Pumping of creams, lotions, gels, toothpastes and shampoos while preserving rheological properties and emulsion stability. Transfer without air incorporation or shearing of structures.

Pharmaceutical Industry

Sterile transfer of ointments, gels, suspensions, syrups and sterile products. GMP compliant design with clean-in-place (CIP/SIP) capability.

Chemistry and Paints

Handling of glues, resins, inks, pigments, varnishes and lacquers. Excellent resistance to chemicals and ability to transfer abrasive or corrosive materials.

Water Treatment

Transfer of urban sludge, industrial sludge and treatment chemicals. Robust against abrasive products and those containing suspended solids.

Ceramics Industry

Pumping of slips, engobes and ceramic pastes while maintaining the homogeneity of the suspensions and preserving the mineral particles.

biotechnology

Transfer of culture media, yeasts and shear-sensitive biological products. Hygienic design with smooth surfaces and no dead zones.

Paper Industry

Pumping of paper pulp, glues and additives with preservation of cellulosic fibers and maintenance of the rheological properties of the mixtures.

Advantages of the progressive cavity principle

Preservation of sensitive products

The gentle transfer through progressive cavities preserves the integrity of particles, fibers, and fragile structures in food products. Whole fruits, vegetable pieces, and crystals remain intact during pumping.

Absence of mechanical shearing that could denature proteins, break emulsions or alter the viscosity of sensitive products.

Exceptional versatility

The same pump can handle products of extremely variable viscosities, from aqueous fluids to very thick pastes, with or without suspended solid particles.

Ability to handle abrasive, corrosive products or products containing up to 70% suspended solids without damage to the pump or alteration of the product.

Precise flow control

The flow rate is directly proportional to the rotation speed, allowing for precise and reproducible dosing. The constant, non-pulsating flow rate ensures uniform product quality.

Fine flow regulation is possible via a variable speed drive to adapt to the precise requirements of production processes.

Operational efficiency

High-performance self-priming allows starting even with empty suction lines. Reversible operation for cleaning or emptying lines.

Simplified maintenance with quick stator replacement without complete pump disassembly, reducing production downtime.

Frequently Asked Questions

Fluid Transfer Products

Hello! Click below to chat with our team on WhatsApp.