Coils - Radiators

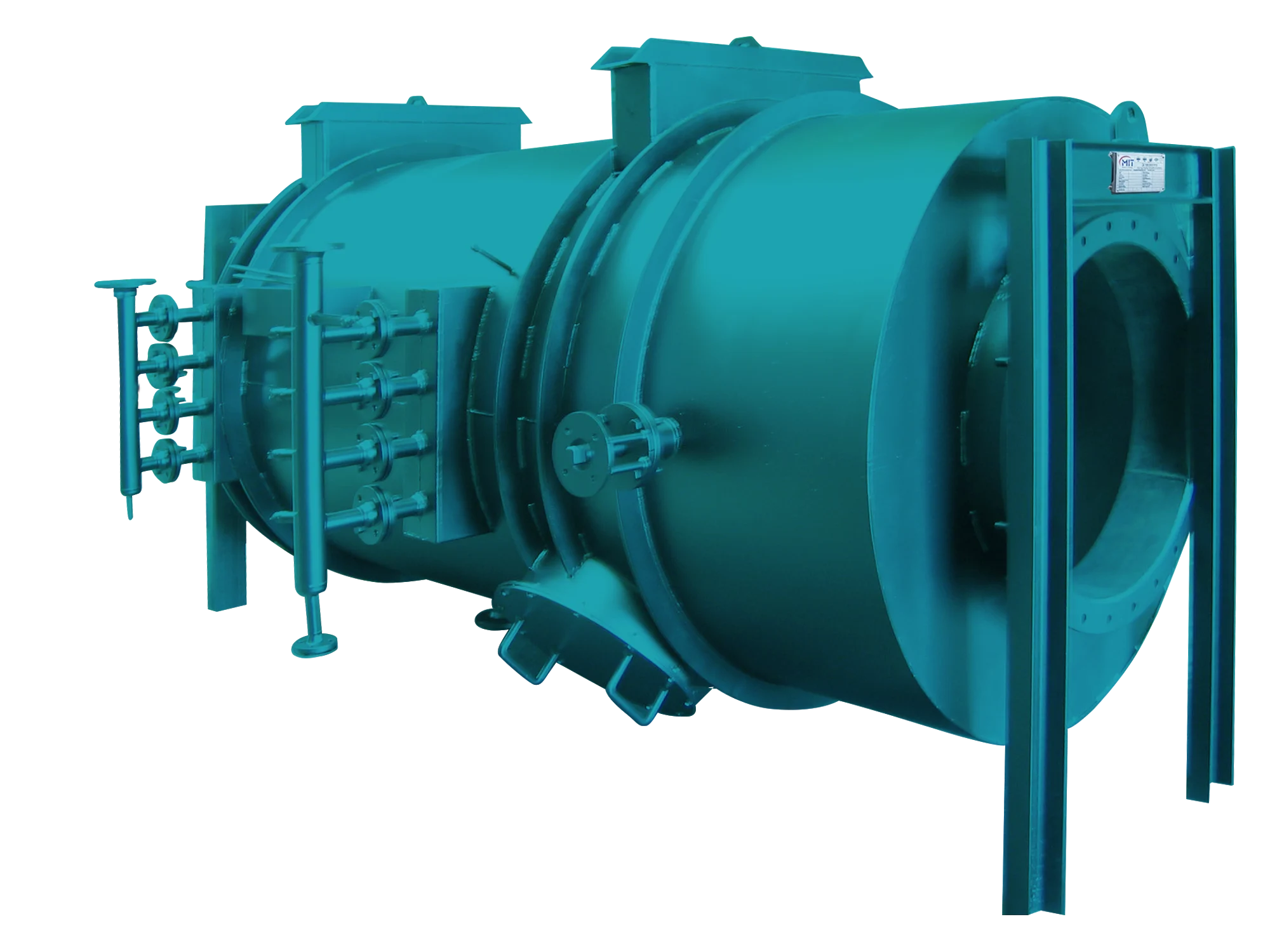

Heat exchangers for all industrial sectors

Radiators are a type of heat exchanger that circulates a gaseous fluid in the primary circuit and a heat transfer fluid or refrigerant in the secondary circuit. Although generally preferred in recycling systems, radiators are used in all sectors and for all applications, depending on the requirements.

Steam: Steam radiators for heating

Hot water: Hot water production and exchange

Hot oil: Oil temperature regulation

Main characteristics of radiators

- Custom design according to the specific requirements of the process

- Durable materials suited to each application

- Extended temperature range depending on the type of radiator

- Operating pressure conforms to PED standards

- Different types of tubes and fins available

- Low pressure drop for optimal energy efficiency

Types of radiators

- Steam radiators: Used to meet heating needs using steam energy

- Hot water radiators: Heat exchangers used to obtain hot water

- Hot oil radiators: A type of radiator used to cool oils or regulate ambient temperature

- Seawater radiators: Specially designed for marine applications

Main components of radiators

Collectors

Function: Distribution and collection of fluids in the system

Available options: U-shaped, flat or domed plugs, tubular collectors, mobile collectors

Selection: Depends on the type of fluid, pressure, and operating temperature

Serpentine resistors

Types: Fin-type or straight-tube depending on the process

Materials: Carbon steel, stainless steel, copper, special alloys

Design: Determined by specific operating conditions

Mirrors and fittings

Materials: Selected according to the system and constraints

Assembly: Welding, mechanical welding, or a combination of both

Customization: Length and thickness adapted to your needs

Serpentine tubes and fin options

Materials available

The materials used in the radiators are determined by the project:

- Tubes: Carbon steel, stainless steel, copper, special alloys (Bafon, brass, etc.)

- Fins: Carbon steel, stainless steel, aluminum, copper

- Combinations: Tubes and fins can be made from different materials suited to the process

Types of coils available

Different configurations to meet all needs:

- Spiral finned coils

- Oval tube coils

- Lamellar-structured coils

- Rubbed tube coils

Industrial application areas

| Industrial sector | Specific applications | Benefits |

|---|---|---|

| Agrifood | Dairy production lines, beverages, fruit juices, breweries | Hygienic, easy-to-clean, food-grade stainless steel solutions |

| Automobile | Production lines, testing systems, paint applications | Compact, high-resistance equipment, energy efficiency, business continuity |

| Marine | Cooling, heating, and marine fluid control systems | Saltwater resistant, low maintenance, long service life |

| HVAC | Air conditioning, domestic hot water production, heating, ventilation | Efficacité énergétique, longévité, optimisation des performances systèmes bâtiment |

| Pétrochimie/Pharma | Procédés haute température/pression, fluides corrosifs et agressifs | Structures robustes, résistance chimique, sécurité procédés critiques |

| Métallurgie | Procédés travail des métaux, lignes de production industrielle | Solutions durables, fiabilité processus, optimisation productivité |

| Énergie | Production électricité, cogénération, récupération chaleur | Haute performance, réduction coûts énergétiques, fonctionnement durable |

| Textile | Impression, teinture, ennoblissement, séchage, contrôle température | Efficacité opérationnelle, optimisation consommation énergie, précision thermique |

Conception et ingénierie

Calculs et normes

- Conception réalisée avec logiciels spécialisés

- Calculs mécaniques conformes norme TEMA

- Respect directive PED 2014/68/UE

- Conformité norme EN 13445

Personnalisation

- Produits fabriqués dans différentes formes

- Adaptation aux exigences spécifiques des procédés

- Conception sur demande selon besoins clients

- Solutions optimisées pour chaque application

Selection of radiators by fluid type

Steam radiators

Used to meet the heating needs of the installation using steam energy:

- Efficient transfer of thermal energy from steam

- Robust design for high temperatures

- Applications in industrial and commercial heating

- Optimization of energy recovery systems

Hot water radiators

Heat exchangers used to obtain hot water in various processes:

- Domestic and industrial hot water production

- Central heating and air conditioning systems

- Heat recovery from wastewater

- Efficient heat exchange water/air or water/water

Hot oil radiators

Type of radiator used for various thermal applications:

- Cooling of unusable industrial oils

- Ambient temperature regulation using oil heat

- Thermal fluid heating systems

- Thermal control in industrial processes

Seawater radiators

Specifically designed for demanding marine environments:

- Exceptional resistance to marine corrosion

- Materials suitable for severe saline conditions

- Naval and offshore applications

- Reduced maintenance in corrosive environments

Selection criteria and optimization

Key factors

The choice of radiators is made by considering several critical parameters:

- Specific conditions of the system and process

- Precise analysis of the permissible pressure drop

- Thermal efficiency required for the application

- Space and installation constraints

- Operational environment and ambient conditions

technical expertise

Our approach guarantees optimal solutions:

- In-depth study of specific needs

- Selecting the right materials for each application

- Precise thermal and mechanical calculations

- Custom-designed for maximum performance

- Compliance with applicable standards and regulations

Complete solutions and technical expertise

Our team of specialist engineers, combined with our expertise in custom design, guarantees high-performance, reliable heat exchange systems tailored to your specific needs. Our radiators offer optimal solutions for heating, cooling, energy recovery, and numerous other industrial and commercial applications.

Materials used depending on the application

Depending on the specific requirements of each process, we use the most suitable materials: Carbon steel, stainless steel, copper, aluminum, special alloys (Bafon, brass) and other specific materials designed to withstand corrosive environments or meet the particular hygienic requirements of your industry.

Frequently Asked Questions

Fluid Transfer Products

Hello! Click below to chat with our team on WhatsApp.