Money Savers

Heat recovery solution for energy efficiency

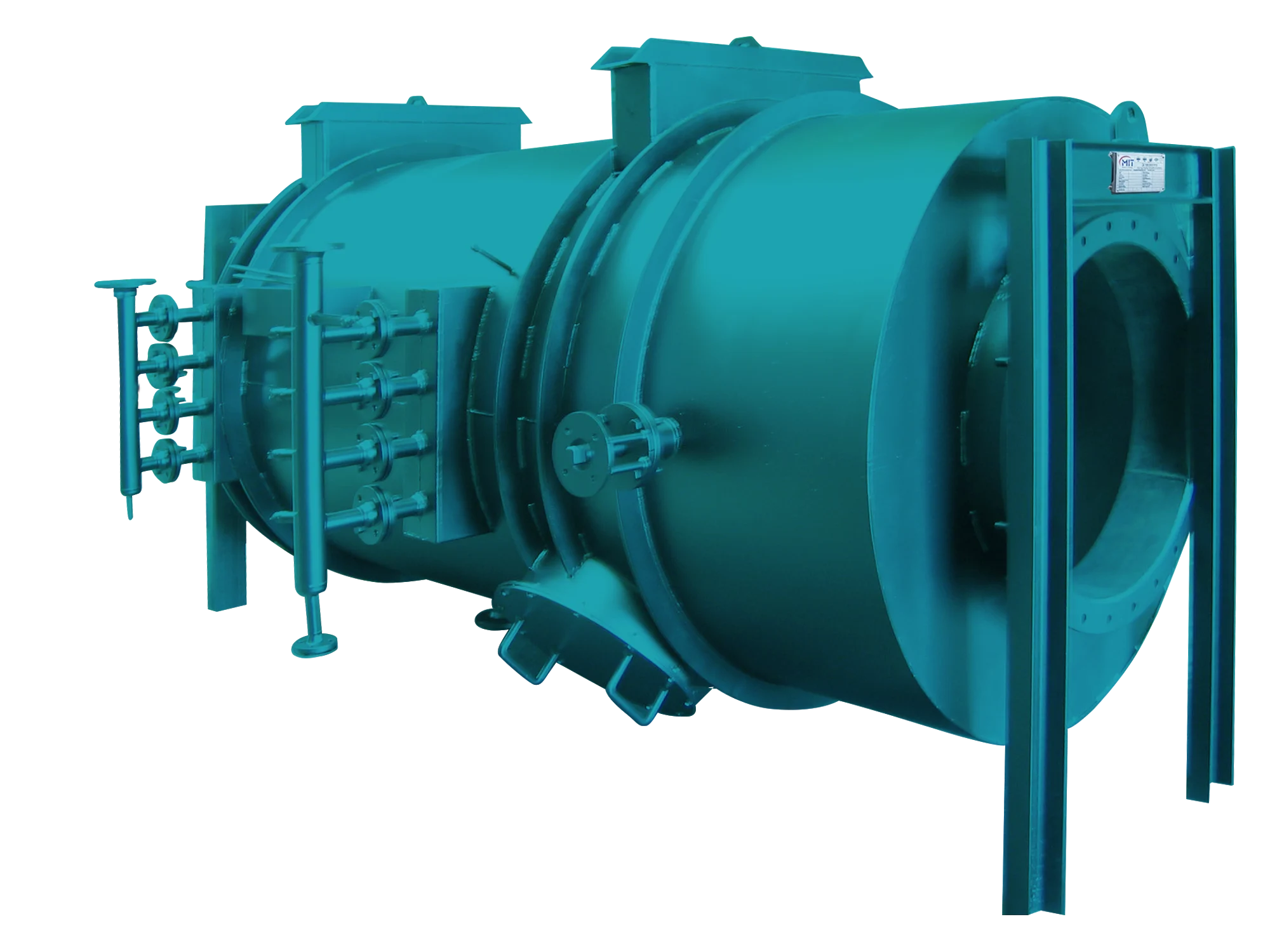

Energy economizers are essential devices that improve the energy efficiency of industrial facilities by recovering heat from waste gases or process fluids. By converting this wasted heat into usable energy, these devices contribute to energy savings and a reduction in environmental impact.

Savings: Up to 30% reduction in energy consumption

Performance: Optimized residual heat recovery

Environment: Reducing carbon footprint and emissions

Types d'économiseurs disponibles

- Économiseurs à ailettes: Tubes à ailettes pour transfert de chaleur élevé, idéal pour applications à faible écart de température

- Économiseurs sans ailettes: Conception simple pour procédés sujets au colmatage, nettoyage facile

- Économiseurs à condensation: Acier inoxydable pour résister à la condensation d'humidité et de soufre dans les gaz résiduaires

- Économiseurs à double rangée: Deux rangées de tubes pour récupération de chaleur accrue, grande capacité

- Économiseurs modulaires: Conception flexible adaptable et extensible selon besoins industriels

Matériaux de construction

- Tubes: Acier inoxydable, acier au carbone, alliages d'aluminium selon application

- Serpentins: Conception spécialisée avec ou sans ailettes pour transfert thermique optimal

- Revêtements: Acier inoxydable pour économiseurs à condensation

- Isolation: Matériaux d'isolation thermique haute qualité pour minimiser les pertes

- Structures: Conceptions personnalisées pour capacités spécifiques

Advantages of economizers

Significant energy savings

Performance: The heat recovered from the waste gases significantly reduces energy consumption

Impact: Up to 30% reduction in energy costs depending on the application

Return on investment: Amortization period generally less than 2 years

Respect for the environment

Emissions reduction: Minimizing environmental impact through increased energy efficiency

Sustainable development: Contribution to carbon footprint reduction objectives

Compliance: Adherence to the strictest environmental standards

Performance and durability

Efficiency: Increased system efficiency for increased production with less energy

Longevity: High-quality materials and innovative engineering solutions for exceptional durability

Reliability: Robust design for continuous operation in industrial environments

Calculating the amortization period

Calculation formula

Payback period (years) = Investment cost / Annual energy savings

This formula makes it possible to determine the time needed to recoup the cost of the device through the energy savings it generates.

Calculation steps

- Investment cost: Determination of the total cost (purchase, installation, transport)

- Annual savings: Calculation based on heat recovery efficiency and energy value

- Amortization period: Dividing the investment cost by the annual savings

Factors influencing the calculation

- Evolution of energy prices over time

- Economizer efficiency and maintenance

- Ongoing operating and maintenance costs

- Site-specific operational conditions

Domaines d'application industriels

| Secteur industriel | Applications spécifiques | Avantages |

|---|---|---|

| Chaudières industrielles | Récupération chaleur gaz résiduaires, optimisation consommation énergie | Amélioration rendement chaudière, réduction coûts combustibles |

| Production d'énergie | Centrales électriques, cogénération, turbines gaz et vapeur | Augmentation efficacité énergétique, réduction pertes thermiques |

| Industrie chimique | Récupération chaleur procédés exothermiques, échangeurs chaleur | Réduction coûts production, optimisation énergétique |

| Pétrochimie | Raffineries, unités de traitement, fours industriels | Solution efficace pour forts écarts température et haute consommation |

| Agroalimentaire | Stérilisation, pasteurisation, séchage, traitement thermique | Efficacité énergétique garantie pour procédés thermiques |

| Pharmaceutique | Récupération chaleur réacteurs, systèmes de stérilisation | Réduction coûts production, conformité normes GMP |

| Métallurgie | Fours de fusion, traitement thermique métaux, fours à induction | Optimisation consommation énergie procédés haute température |

| Textile | Teinture, séchage, impression, traitement fibres | Amélioration efficacité opérationnelle, optimisation consommation |

Composants de fabrication

Éléments thermiques

- Tubes en acier inoxydable ou acier au carbone

- Serpentins spécialement conçus pour refroidissement efficace

- Ailettes pour optimisation transfert thermique

- Conceptions personnalisées selon capacité requise

Protection et isolation

- Revêtements acier inoxydable anti-condensation

- Isolation thermique haute performance

- Structures support renforcées

- Systèmes anti-colmatage intégrés

Custom design and manufacturing

Custom engineering

Our economizers are custom-designed by our specialist engineers:

- Detailed study of each client's specific needs

- Use of specialized software for precise thermal calculations

- Optimal selection of materials according to the environment

- Compliance with international standards (EN 12952-3, EN 13445-3, ASME)

Manufacturing process

Our process guarantees quality and performance:

- Manufactured in accordance with the strictest quality standards

- Quality controls at each stage of production

- Systematic pressure and performance testing

- Complete technical documentation provided

Detailed sector-specific applications

Energy-intensive industries

- Petrochemicals: Effective solution for large temperature variations

- Metallurgy: Energy optimization of high-temperature processes

- Energy production: Increased efficiency of power plants

- Cement plant: Heat recovery from kilns and coolers

Process industries

- Food processing: Energy efficiency for production lines

- Pharmaceuticals: Reducing production costs for sterile processes

- Chemistry: Heat recovery from reactors and columns

- Textiles: Energy optimization of dyeing and drying

Economic and environmental benefits

Economic advantages

- Energy cost reduction of up to 30%

- Amortization period generally less than 2 years

- Reduction in operating and maintenance costs

- Increased competitiveness through cost reduction

Environmental impacts

- Significant reduction in CO2 emissions

- Reduction of the carbon footprint of facilities

- Optimizing the use of energy resources

- Contribution to the Sustainable Development Goals

Our commitment to quality

All our energy savers are manufactured using durable, high-quality materials, adhering to the strictest international standards. Our production processes are designed to provide our customers with high-performance, reliable solutions, ensuring substantial energy savings and a reduced environmental impact.

Frequently Asked Questions

Fluid Transfer Products

Hello! Click below to chat with our team on WhatsApp.