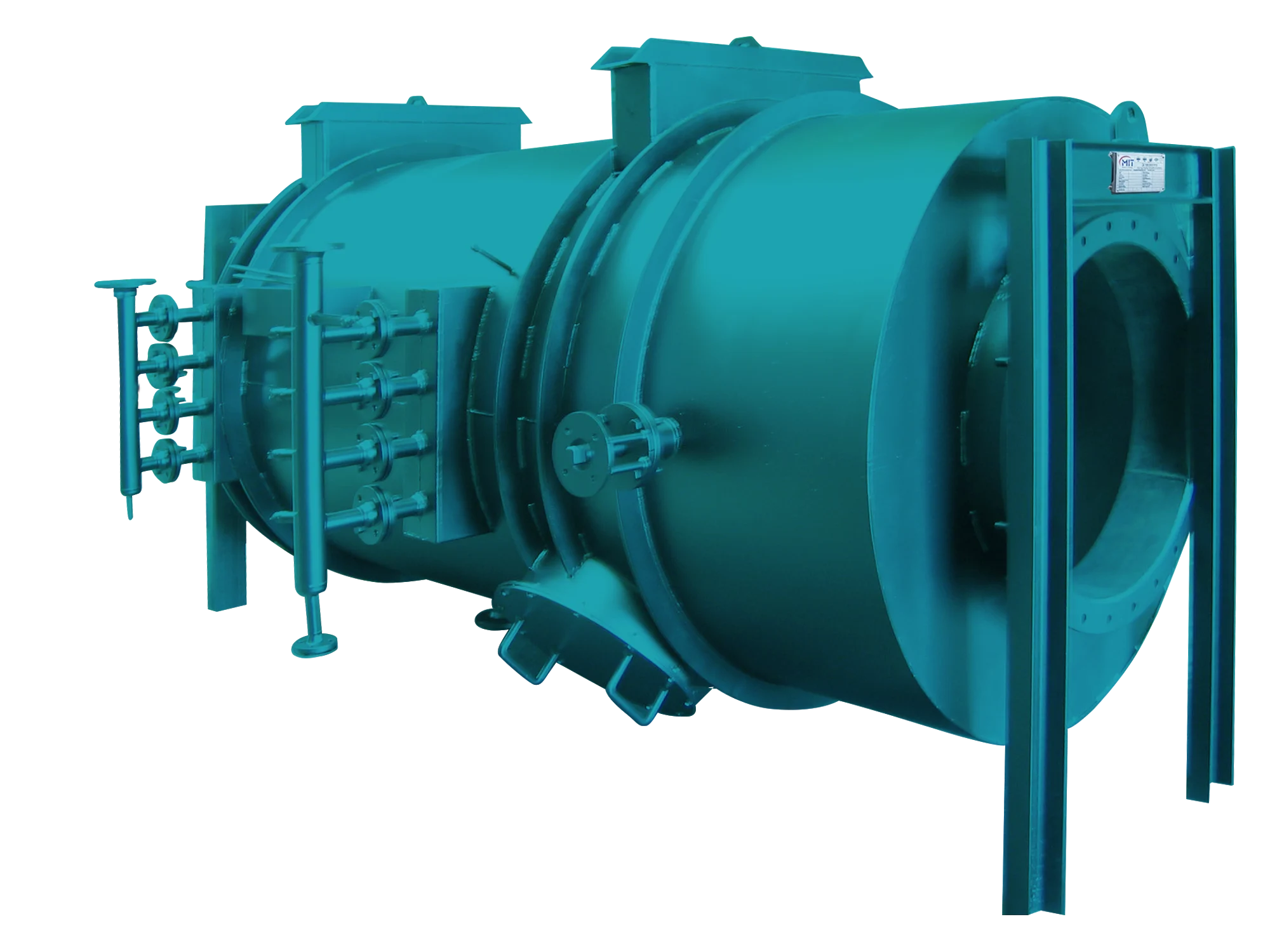

Heating coils

Complete solutions for HVAC systems

Direct expansion (DX) heating, cooling, and cooling coils are a type of heat exchanger primarily used in HVAC (heating, ventilation, and air conditioning) systems to treat air and maintain desired indoor climate conditions. Their main function is to facilitate heat transfer between the air and the fluid (refrigerant, water, or steam) circulating in the tubes.

Heating: Heat transfer from hot water/steam to air

Cooling: Heat absorption from air to fluid

DX: Direct expansion refrigerant

Caractéristiques principales des serpentins

- Conception optimisée pour une efficacité maximale du transfert de chaleur

- Matériaux résistants à la corrosion : cuivre, aluminium, acier inoxydable

- Plage de température : -20°C à +200°C selon l'application

- Pression de service jusqu'à 25 bar

- Ailettes plates ou ondulées pour surface d'échange maximisée

- Faible perte de charge pour une économie d'énergie optimale

- Certifications CE, ISO 9001:2015, normes CVC

Matériaux de construction

- Tubes : Cuivre, acier inoxydable selon application

- Ailettes : Aluminium, aluminium époxy (bleu et or), cuivre, acier inoxydable

- Collecteurs : Laiton, acier, acier inoxydable

- Cadres : Acier galvanisé, aluminium, acier inoxydable

Types of coils and their applications

Heating Coils

Function: To transfer heat from hot water or steam to air

Applications: Air handling units, heating systems, ventilation units

Features: Robust design for high temperatures, low pressure drop

Cooling Coils

Function: To absorb heat from the air to cool or dehumidify.

Applications: Air conditioning systems, industrial cooling, dehumidification

Features: Optimized heat exchange surface, resistance to condensation

Direct Release (DX) Coils

Function: Direct expansion of the refrigerant in the closed circuit

Applications: VRF systems, comfort air conditioning, indoor units

Features: Copper tubes, aluminum fins, compact design

Manufacturing process

Custom design

The coils are manufactured to the desired dimensions and capacities to meet specific customer needs. Our process includes:

- Precise thermal calculations to determine the optimal product

- Selection of materials adapted to the process and the environment

- Determining tube diameters according to requirements

- Custom design for each application

Assembly and quality control

Our manufacturing process guarantees optimal quality:

- Precise stacking of the fins according to specifications

- Automated mechanical inflation for perfect thermal contact

- Rigorous quality control at every stage

- Systematic pressure and leak tests

Domaines d'application industriels

| Secteur industriel | Applications spécifiques | Avantages |

|---|---|---|

| Agroalimentaire | Chambres froides, tunnels de refroidissement, traitement d'air hygiénique | Surfaces lisses, nettoyage facile, conformité aux normes alimentaires |

| Automobile | Cabines de peinture, systèmes de ventilation, salles de test environnemental | Fiabilité élevée, résistance aux environnements sévères |

| Marine | Climatisation navale, ventilation des espaces, systèmes de chauffage | Résistance à la corrosion marine, conception compacte |

| CVC | Centrales de traitement d'air, systèmes de climatisation, ventilation | Haute efficacité énergétique, faible niveau sonore, longue durée de vie |

| Pétrochimie/Pharma | Contrôle température zones propres, ventilation laboratoires, procédés | Résistance chimique, conformité aux normes GMP |

| Métallurgie | Ventilation ateliers, refroidissement équipements, traitement air | Robustesse, résistance aux environnements poussiéreux |

| Énergie | Ventilation centrales, contrôle température locaux techniques | Performance optimale, fiabilité en continu |

| Textile | Contrôle humidité ateliers, ventilation zones production, séchage | Précision climatique, efficacité énergétique |

Fonctionnement des systèmes CVC

Cycle de Chauffage

- Transfert de chaleur du fluide caloporteur vers l'air

- Utilisation d'eau chaude, vapeur ou réfrigérant chaud

- Maintenance des températures de confort en hiver

- Élément essentiel des centrales de traitement d'air

Cycle de Refroidissement

- Absorption de chaleur de l'air vers le fluide frigorigène

- Refroidissement et déshumidification de l'air

- Maintenance des températures de confort en été

- Composant clé des systèmes de climatisation

Specific applications of coils

Ventilation systems

Coils are essential in air handling systems:

- Fresh and recycled air handling units

- Dual-flow ventilation units with heat recovery

- Air heating and cooling systems

- Central air conditioning units

Industrial applications

In industrial environments, coils provide:

- Climate control of production workshops

- Ventilation of controlled atmosphere zones

- Cooling of industrial processes

- Dehumidification of storage spaces

Design and selection of coils

Design factors

The design of the coil directly impacts the system's efficiency:

- Thermal capacity adapted to the requirements

- Material selection according to the environment

- Optimization of the exchange surface

- Reduction of pressure losses

Maintenance and durability

To guarantee performance and longevity:

- Regular cleaning of the fins

- Circuit leak testing

- Thermal performance monitoring

- Protection against corrosion and fouling

Tailor-made solutions and technical expertise

Our team of expert engineers, combined with our expertise in customized solutions, ensures high-performance and reliable air handling systems. Our products offer ideal solutions for air conditioning, heating, ventilation, and many other industrial and commercial applications.

Materials used

Depending on the requirements of the process, we use the following materials: Copper, aluminum, stainless steel, special alloys and other specific materials suitable for corrosive environments or particular hygienic requirements.

Frequently Asked Questions

Fluid Transfer Products

Hello! Click below to chat with our team on WhatsApp.