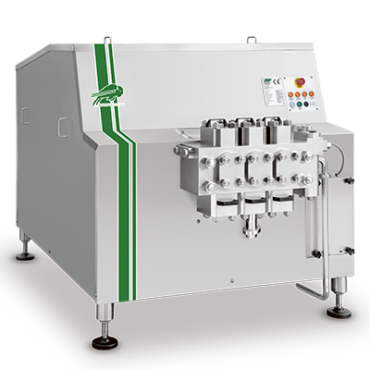

Milk Collection System - Complete Solution

Milk Reception and Storage Systems

Complete solutions for the collection, degassing and storage of raw milk

Our milk receiving systems are specifically designed to meet the stringent requirements of dairies and collection centers. They combine vacuum technology, hygienic design, and complete automation to ensure fast and secure milk collection while preserving its quality.

Type: Vacuum receiving units and collection systems

Application: Dairy collection centers and dairy industries

Advantage: Fast collection, efficient degassing, and complete automation

Main features of the Milk Reception System

- Processing capacity: 5 to 50 tons/hour depending on configuration

- Technology: Vacuum system for foam-free reception

- Degassing: Effective elimination of unwanted air and odors

- Materials: Food-grade AISI 304/316L stainless steel

- Automation: Fully automated system with software control

- Cleaning: Integrated and automated Clean-In-Place (CIP)

- Control: Inline vacuum sensor for end-of-unloading detection

- Traceability: Automatic recording of all collection data

- Design: Compact and pre-assembled for quick installation

- Certifications: CE, FDA, food safety standards

Full description

Our vacuum receiving system represents the pinnacle of milk collection for collection centers and dairies. Designed specifically for the rapid and efficient unloading of raw milk from tanker trucks or drums, it combines advanced vacuum technology with complete automation to guarantee the safety and quality of the raw material.

The "foam-free" technology allows for vacuum collection, which performs initial degassing and deodorization of the milk. This air removal significantly improves milk quality by preserving its sensory and nutritional characteristics, while also enabling precise measurement of the quantity received and creating optimal conditions for subsequent processing such as skimming.

These systems are particularly well-suited for dairy industries seeking to optimize their receiving operations while ensuring reliability, food safety, and profitability. The modularity of the options allows for perfect adaptation to your specific capacity and automation needs.

Technical data of the Milk Reception System

| Setting | Specifications |

|---|---|

| Equipment type | Vacuum milk receiving unit |

| Processing capacity | 5 to 50 tonnes/hour |

| Technology | Foam-free vacuum system |

| Operating pressure | Vacuum up to 0.8 bar |

| Milk source | Tank trucks and drums |

| building materials | AISI 304/316L |

| Degassing | Air removal and deodorization |

| Automation | Fully automated system |

| Cleaning | Integrated and automated CIP |

| Control | Vacuum sensor and dedicated software |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| Foam-free vacuum receiving system | Automatic milk sampling system |

| Integrated degassing and deodorization | Printer for data collection |

| Automated Clean-In-Place (CIP) | Plate heat exchanger for milk cooling |

| Dedicated control software | Advanced monitoring and traceability system |

| Vacuum sensor for end detection | Industrial programmable logic controller |

| Automatic data recording | Touchscreen user interface |

| Compact, pre-assembled design | Complete hygienic fairing |

| Milk recovery from the pipes | Backup power outage system |

FEATURES DETAILS

Foam-free vacuum system

Our patented vacuum receiving technology allows for milk collection without foaming, with initial degassing and deodorization. This optimized design preserves the milk's organoleptic qualities, enables precise volume measurement, and prepares the milk for subsequent processing such as skimming.

Complete automation

The system is fully automated thanks to dedicated software which controls the initial unloading, the recovery of milk in the pipes at the end of collection, the automatic stop when the tank is empty (via inline vacuum sensor), the CIP cleaning and the recording of all collection data for total traceability.

Compact and efficient design

The system's pre-assembled and compact design allows for quick and easy installation. The efficiency of the vacuum system significantly reduces unloading times while ensuring gentle handling of the milk, preserving its quality and food safety.

Areas of application

Our milk receiving systems are suitable for various applications in the dairy industry:

- Milk collection centers - Reception and degassing of raw milk from tanker trucks and drums

- Processing dairies - Initial reception of milk before processing and transformation

- Dairy cooperatives - Centralized collection from multiple producers

- Industrial cheese factories - Reception and pretreatment of milk for cheese production

- UHT/pasteurized milk production units - First stage of the processing chain

- Milk drying facilities - Reception and degassing before the drying process

Advantages of the milk reception system

Fast and compact reception

The system's compact, pre-assembled design allows for quick and easy installation. Vacuum receiving significantly speeds up milk unloading time (from 5 to 50 tons/hour), optimizing operational efficiency and reducing truck waiting times.

Milk quality improvement

The system removes air and unwanted odors from the milk upon receipt, improving sensory quality, preserving nutritional value, and extending shelf life. This initial deaeration also enhances the accuracy of quantitative measurement and creates optimal conditions for subsequent processing such as skimming.

Fully automated process

Complete automation of the receiving, product retrieval from the pipes, empty stop (via an inline sensor), CIP cleaning, and data logging phases. The system generates comprehensive reports for each supplier (producer code, collector, date, time, quantity, temperature, etc.), ensuring complete traceability.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.