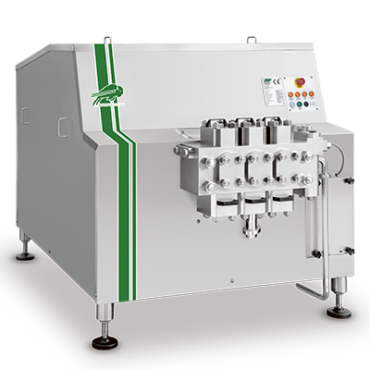

Centrifugal Milk Separator

Centrifugal Milk Separator

Advanced centrifugal separation technology for precision cream separator

Our high-performance centrifugal separator is specially designed for milk skimming, combining exceptional separation efficiency with gentle treatment of fat globules and optimized energy consumption.

Type: Hermetic centrifugal separator

Application: Skimming milk and separating cream/skimmed milk

Advantage: Separation efficiency > 99.8%

Main features of the Centrifugal Separator

- Airtight design for smooth product entry/exit without air introduction

- Integrated PRSTM system to reduce milk loss to almost zero during discharge

- Processing capacity: 60 to 50,000 liters/hour depending on configuration

- Superduplex stainless steel bowl for exceptional durability

- Direct gear transmission with flexible spindle vertical shaft

- Automatic discharge of solids without interruption of the process

- Constructed entirely of food-grade stainless steel

- PLC control with 15" touchscreen HMI interface and real-time monitoring

- Integrated rotary pumps for skimmed milk and cream

Full description

Our centrifugal milk separator represents excellence in dairy separation technology. Designed specifically for skimming milk, it combines maximum separation efficiency with gentle treatment of fat globules.

The patented airtight design ensures that the product enters the bowl smoothly and gradually accelerates to the separation speed. This system prevents air from entering the flow and guarantees gentle processing that preserves the quality of the fat globules.

This separator is particularly suitable for dairies seeking to optimize their production of cream and skimmed milk, offering exceptional yield while minimizing product loss and energy consumption.

Technical data of the Centrifugal Separator

| Setting | Specifications |

|---|---|

| Machine type | Airtight centrifugal milk separator |

| Processing capacity | 60 - 50,000 L/hour |

| Rotation speed | 6,500 - 9,500 rpm (depending on model) |

| Force centrifuge | Up to 10,000 xg |

| Fat content of skimmed milk | < 0.05% (adjustable) |

| Fat content cream | 30-50% (adjustable) |

| Operating pressure | Up to 6 bar |

| Materials in contact | Superduplex steel, AISI 316L, EPDM |

| Electricity consumption | 15-90 kW depending on capacity |

| Sludge chamber volume | 10-25 L depending on the model |

| Solid discharge frequency | Variable depending on milk turbidity |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| Airtight design without air introduction | Online fat monitoring system |

| PRSTM system for reducing protein losses | Online density controller |

| Automatic discharge of solids | SIP sterilization system |

| Integrated rotary pumps | Online bacterial analyzer |

| 15" Touchscreen User Interface | Ethernet connection and monitoring |

| Recording of HACCP parameters | Complete traceability system |

| Direct gear transmission | Acoustic fairing |

| Protection IP65 | Complete hygienic fairing |

FEATURES DETAILS

Patented airtight design

Our airtight inlet/outlet system ensures that the milk enters the bowl smoothly and gradually accelerates to the separation speed. This technology prevents air from being introduced and preserves the integrity of the fat globules, which is essential for the quality of the cream produced.

PRSTM protein recovery system

The PRSTM (Protein Recovery System) reduces milk losses to almost zero during solids discharge. Thanks to an optimized sludge chamber and a faster, more powerful discharge system, we minimize product loss while maintaining maximum separation efficiency.

Direct transmission and energy efficiency

The direct drive system with a special motor mounted directly on the centrifugal shaft minimizes energy loss, reduces space requirements, and decreases maintenance needs. Combined with a special frequency inverter, it optimizes power consumption for economical operation.

Areas of application

Our centrifugal separator is suitable for various applications in the dairy industry:

- Skimming of standard milk - Production of skimmed milk and cream

- Milk standardization - Precise adjustment of fat content

- Milk clarification - Removal of impurities and somatic cells

- Buttermilk production - Separation during butter making

- Whey processing - Separation of fat and protein phases

Advantages of centrifugal separation

Optimal separation efficiency

With a separation efficiency exceeding 99.8%, our technology guarantees precise cream/skimmed milk separation while preserving the quality of fat globules for a cream with superior texture and taste.

Significant energy savings

Direct drive and the absence of an additional recovery pump significantly reduce energy consumption, while integrated rotary pumps maximize product transfer efficiency.

Reduced maintenance and reliability

With fewer moving parts and a robust design, our separator offers exceptional reliability and minimized maintenance costs, ensuring continuous productivity and optimized operating costs.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.