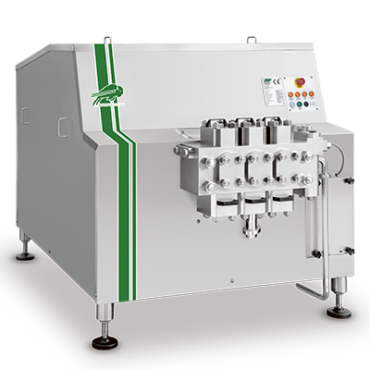

HTST Pasteurizer for Fresh Milk - High Performance

HTST Pasteurizer for Fresh Milk

Gentle heat treatment technology for optimal quality and extended lifespan

Our HTST (High Temperature Short Time) pasteurizer is specially designed for the processing of fresh milk, combining effective elimination of pathogenic microorganisms with maximum preservation of the natural taste, vitamins and nutritional properties of the milk.

Type: High-efficiency plate HTST pasteurizer

Application: Fresh whole, skimmed and standardized milk

Advantage: Optimal preservation of taste and nutritional qualities

Main features of the HTST Pasteurizer

- High-precision HTST heat treatment: 72-75°C for 15-30 seconds

- Elimination of pathogenic microorganisms while preserving beneficial flora

- Processing capacity: 1,000 to 15,000 liters/hour depending on configuration

- Stainless steel AISI 316L plate heat exchanger

- Energy recovery > 90% for maximum energy efficiency

- Temperature control system ±0.5°C

- Constructed entirely of food-grade stainless steel

- Certifications : CE, FDA, EHEDG, 3-A Sanitary Standards

- PLC control with 15" touchscreen HMI interface and data logging

- Integrated CIP automatic cleaning system

Full description

Our HTST pasteurizer for fresh milk represents excellence in gentle heat treatment of dairy products. Designed specifically to preserve the natural qualities of fresh milk, it combines effective elimination of pathogens with exceptional preservation of taste, vitamins, and nutritional properties.

Plate heat exchanger technology ensures rapid and uniform heat transfer, preventing localized overheating that could damage milk proteins and alter the delicate taste of fresh milk. The precision temperature control system guarantees perfectly reproducible processing, essential for the consistent quality of the finished product.

This pasteurizer is particularly suitable for dairies seeking to produce high-quality fresh milk with an optimal shelf life while maintaining its natural organoleptic characteristics intact.

Technical data of the HTST Pasteurizer

| Setting | Specifications |

|---|---|

| Machine type | HTST plate pasteurizer for fresh milk |

| Processing capacity | 1,000 - 15,000 L/hour |

| Pasteurization temperature | 72-75°C (adjustable) |

| Holding time | 15-30 seconds |

| Cooling temperature | 4-6°C |

| Energy recovery | > 90% |

| Operating pressure | Up to 10 bar |

| Materials in contact | AISI 316L, EPDM, NBR |

| Steam consumption | 20-120 kg/hour depending on capacity |

| Cooling water consumption | 2-6 m³/hour |

| Installed electrical power | 10-60 kW |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| High-efficiency plate heat exchanger | Deaeration system |

| Temperature-controlled holding section | Automatic standardization of fat |

| Automatic CIP cleaning | integrated homogenization system |

| Precise temperature regulation | Online conductivity tester |

| 15" Touchscreen User Interface | Ethernet connection and monitoring |

| Saving settings | Complete HACCP traceability system |

| Automatic diverter valve | Airless milk evaporator |

| Protection IP65 | Complete hygienic fairing |

FEATURES DETAILS

Gentle heat treatment for condoms

Our HTST technology ensures the complete destruction of pathogenic microorganisms while preserving the natural structure of proteins, heat-sensitive vitamins, and the authentic taste of fresh milk. The cold chain remains intact throughout the entire process.

Intelligent control system

Advanced PID control maintains a temperature accuracy of ±0.5°C in all sections of the process. Redundant sensors ensure safe processing and compliance with HACCP standards, essential for fresh dairy products.

Concept Plug-and-Play

Simplified installation with semi-automatic or fully automatic configuration, allowing for rapid integration into any existing dairy. Reduced commissioning times thanks to a modular and standardized design.

Areas of application

Our HTST pasteurizer is suitable for various applications in the dairy industry:

- Fresh whole milk - Optimal preservation of taste and nutritional qualities

- Skimmed and standardized milk - Production of milk with different fat content

- Fresh cream - Liquid cream for direct consumption or processing

- Flavored milk - For chocolate, vanilla and other flavored milks

- Cheese preparations - For fresh cheeses and curds

Advantages of HTST treatment

Maximum food safety

Effective elimination of all pathogenic microorganisms while adhering to the strictest food safety standards. Compliant with current international regulations.

Exceptional product quality

Maximum preservation of the organoleptic qualities, natural vitamins and nutritional properties of the milk. Authentic taste and creamy texture preserved.

Energy efficiency

With over 90% energy recovery, our pasteurizer significantly reduces steam and cooling water consumption, offering optimized operating costs.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.