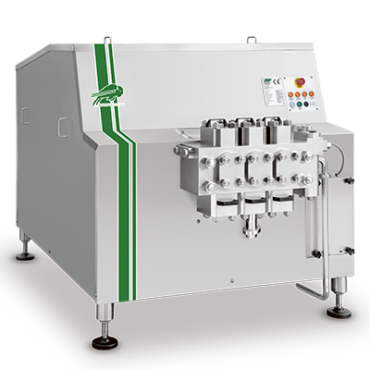

ESL Milk Pasteurizer - Advanced Technology

ESL Milk Pasteurizer

Integrated super-pasteurization and bactofugation technology for extended shelf life

Our ESL pasteurizer incorporates advanced technology combining high-precision heat treatment and mechanical removal of bacterial spores, enabling the production of milk with characteristics similar to traditional pasteurized milk but with a significantly extended shelf life.

Type: Integrated ESL pasteurization system with bactofugation

Application: ESL milk and long-life fresh dairy products

Advantage: Can be stored for up to 30 days while preserving its original qualities.

Key features of the ESL Pasteurizer

- Super-pasteurization treatment: 125-135°C with ultra-short holding time

- Integrated bactofugation at 60°C for the mechanical elimination of heat-resistant spores

- Bacterial reduction > 6 log (99.9999%) including aerobic spores

- Processing capacity: 2,000 to 25,000 liters/hour depending on configuration

- Triple-effect plate heat exchanger in AISI 316L stainless steel

- Integrated deaeration system for the removal of oxygen and volatile compounds

- Energy recovery > 92% for maximum energy efficiency

- Constructed entirely of hygienic-grade stainless steel

- Certifications : CE, FDA, EHEDG, 3-A Sanitary Standards, ISO 22000

- Automation PLC with 15" touchscreen HMI interface and HACCP data logging

- Integrated CIP and SIP (Sterilize-in-Place) systems

Full description

Our ESL milk pasteurizer represents a technological advancement in the processing of fresh dairy products with extended shelf life. The system intelligently combines high-temperature super-pasteurization with mechanical bactofugation, eliminating heat-resistant bacterial spores without altering the organoleptic qualities of the milk.

The integrated deaeration technology eliminates oxygen and unwanted volatile compounds, preserving the product's freshness and natural aromas. The precise and rapid heat treatment prevents the denaturation of milk proteins and preserves sensitive vitamins and enzymes.

This comprehensive solution also integrates clarification, automatic inline standardization, homogenization and aseptic packaging, offering dairies a fully automated and optimized ESL production platform.

Technical data of the ESL Pasteurizer

| Setting | Specifications |

|---|---|

| System type | Integrated ESL pasteurizer with bactofugation |

| Processing capacity | 2,000 - 25,000 L/hour |

| super-pasteurization temperature | 125-135°C (adjustable) |

| Ultra-pasteurization holding time | 2-4 seconds |

| Bactofugation temperature | 60°C |

| Bactofugation efficacy | Elimination of >98% of spores |

| Final cooling temperature | 4-6°C |

| Energy recovery | > 92% |

| Homogenizer service pressure | Up to 250 bar |

| Noise level | 75 dB(A) |

| Steam consumption | 20-120 kg/hour depending on capacity |

| Installed electrical power | 25-150 kW |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| Integrated bactericide for spore elimination | Membrane filtration system |

| Vacuum deaerator for O₂ removal | Advanced aseptic pasteurization |

| High-pressure homogenizer | Evaporative concentration system |

| Automatic online standardization | Online analyzers (fat, protein) |

| Automated CIP/SIP systems | Industry 4.0 and IoT Connectivity |

| Complete HACCP data recording | Complete product traceability system |

| 15" Touchscreen User Interface | Central supervision and remote control |

| IP66 protection for humid environments | Complete hygienic stainless steel casing |

FEATURES DETAILS

Integrated bactofugation technology

The mechanical bactericide specifically eliminates heat-resistant aerobic bacterial spores at a temperature of 60°C, effectively complementing the action of super-pasteurization. This unique combination achieves exceptional microbial reduction while preserving the sensory qualities of fresh milk.

Advanced deaeration system

The vacuum deaerator removes dissolved oxygen and microbubbles of air, reducing oxidation and preserving product freshness. It also acts as a deodorizer, eliminating unwanted volatile compounds that can affect the taste of milk depending on the season and the livestock's diet.

Automation and process control

The advanced PLC system guarantees perfectly reproducible product processing. Pasteurization temperatures, diverter valve parameters, and all critical data are continuously recorded and monitored, ensuring compliance with the strictest food safety standards.

Areas of application

Our ESL pasteurizer is the ideal solution for various applications in the modern dairy industry:

- Premium ESL milk - Shelf life of up to 30 days at 4-6°C with optimal organoleptic quality

- Long-life flavored milk - For chocolate, vanilla and other flavored milks

- ESL Creams - Liquid fresh cream, dessert creams and whipped creams

- Fresh cheese preparations - Soft cheeses, fresh cheeses and dairy specialties

- Functional Dairy Drinks - Fermented Milks, Probiotic Products and Fortified Beverages

Benefits of ESL treatment

Exceptional preservation of quality

ESL technology preserves native vitamins, enzymes and proteins better than traditional UHT sterilization, while offering a significantly longer shelf life than standard pasteurized milk, maintaining the freshness, taste and nutritional value of the product.

Extended logistical flexibility

With a shelf life of up to 30 days, ESL milk allows for optimized stock management, drastic reduction of losses and expanded distribution to regional and national markets, significantly increasing commercial coverage.

Profitability and sustainability

The combination of extended lifespan, reduced returns and optimized operating costs thanks to exceptional energy efficiency offers a rapid return on investment and sustainable production.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.