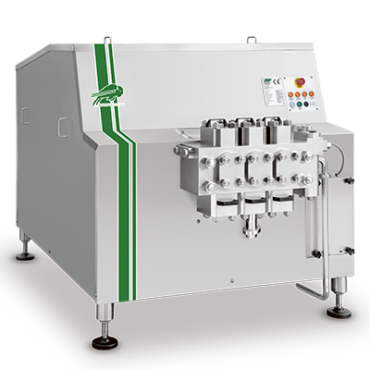

High-Pressure Industrial Homogenizers

Industrial Homogenizers

Advanced high-pressure homogenization technology for optimal stability and quality

Our industrial homogenizers represent technological excellence in the field of particle micronization and dispersion. Designed to ensure exceptional product stability even after further processing and prolonged storage, they guarantee superior results in the food, pharmaceutical, cosmetic, and chemical sectors.

Type: High-pressure piston homogenizers

Application: Food, pharmaceutical, cosmetic and chemical sectors

Advantage: Pressure up to 1,500 bar and capacities from 50 to 50,000 L/h

Main characteristics of homogenizers

- High-pressure homogenization technology with pressures up to 1,500 bar

- Extended capacity range: from 50 to 50,000 liters/hour depending on configuration

- Particle size reduction down to the submicron scale

- Constructed entirely of hygienic AISI 316L stainless steel

- Multi-piston system with high-life ceramic seals

- Homogenizing block with optimized geometry for maximum efficiency

- PLC automation with touchscreen HMI interface and parameter logging

- Optimized energy consumption with energy recovery

- Certifications: CE, FDA, EHEDG, 3-A Sanitary Standards, ATEX (optional)

- Integrated CIP (Clean-in-Place) systems for automatic cleaning

- Hygienic design with smooth surfaces and rounded corners

Full description

Industrial homogenizers represent the cutting edge of technology in the field of particle reduction and dispersion. Thanks to their patented high-pressure system, they achieve extremely fine and uniform particle distributions, guaranteeing exceptional stability of the final products.

The homogenization technology relies on a principle of combined forces: shear, turbulence, and cavitation, applied in a controlled manner within the homogenization chamber. This process ensures efficient reduction of fat globules, perfect dispersion of emulsifiers, and homogeneous distribution of solid particles.

Our machines are designed for maximum reliability and durability, with superior quality components and precision engineering that ensure consistent performance over time, even under intensive operating conditions.

Technical data for FBF Homogenizers

| Setting | Specifications |

|---|---|

| System type | High-pressure multi-piston homogenizer |

| Processing capacity | 50 - 50,000 L/hour |

| Maximum homogenization pressure | Up to 1,500 bar |

| Standard working pressure | 100 - 600 bar (depending on application) |

| Number of pistons | 3, 5 or 7 depending on the model and capacity |

| Engine power | 5.5 - 450 kW depending on capacity and pressure |

| Noise level | < 75 dB(A) with acoustic shroud |

| Maximum product temperature | 90°C (120°C with specific options) |

| Cooling water consumption | 1-20 m³/h depending on the model |

| Power supply | 400V / 50Hz or customizable |

| Weight | 500 - 15,000 kg depending on the model |

| Clutter | Variable depending on capacity and configuration |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| Forged stainless steel homogenizing block | Enhanced cooling for sensitive products |

| High-pressure multi-piston pump | Integrated degassing system |

| Homogenization valve with optimized geometry | Data recording compliant with FDA 21 CFR Part 11 |

| PLC automation with touchscreen | Online flow and pressure controllers |

| Integrated automatic CIP system | Packages ATEX pour zones explosives |

| High-precision pressure and temperature sensors | Industry 4.0 Communication Interface |

| Acoustic and protective fairing | Special finishes (electropolishing, etc.) |

| IP55 protection for industrial environments | Steam sterilization modules (SIP) |

FEATURES DETAILS

Patented homogenization block technology

The FBF homogenization block is designed with an optimized geometry that maximizes process efficiency while minimizing wear. The unique combination of impact, shear, and cavitation enables the achievement of extremely fine particle distributions with reduced energy consumption.

High-performance piston system

The piston-cylinder assemblies are manufactured from ceramic materials and special heat-treated steels for exceptional durability. The automatic lubrication system and high-performance seals ensure reliable operation even at the highest pressures.

Advanced process automation and control

The PLC control system allows for precise adjustment of all operational parameters: pressure, flow rate, and temperature. The intuitive user interface provides a complete visualization of the process and automatic data recording for traceability and quality analysis.

Areas of application

Our industrial homogenizers are the ideal solution for numerous applications in various sectors:

- Dairy industry - Homogenization of milk, creams, dairy desserts, ice cream

- Pharmaceutical products - Injectable emulsions, suspensions, liposomes, vaccines

- Cosmetics - Creams, lotions, emulsions, hair products

- Chemical industry - Pigments, inks, polymers, nanomaterials

- Food and drinks - Juices, sauces, mayonnaise, tomato-based products

Advantages of high-pressure homogenization

Exceptional product stability

High-pressure homogenization produces extremely fine and uniform particle distributions, eliminating sedimentation, creaming, and phase separation. The products retain their stability even after months of storage.

Improvement of organoleptic properties

Reducing the size of fat globules and solid particles significantly improves the texture, consistency, and mouthfeel of the products. Flavors are better released, and colors are more intense and stable.

Increased efficiency and productivity

FBF homogenizers offer optimal energy efficiency with reduced consumption. Their robust design and advanced automation guarantee continuous production with minimal intervention and maintenance.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.