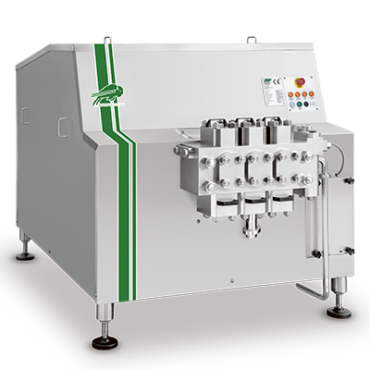

Vacuum Milk Evaporator

Vacuum Milk Evaporator

Low-temperature concentration technology for optimal preservation

Our high-performance vacuum evaporator is specially designed for milk concentration, removing air and dissolved gases while preserving the nutritional and organoleptic qualities of the product through low-temperature processing.

Type: Vacuum Falling Film Evaporator

Application: Concentration of milk and dairy products

Advantage: Preserves nutrients and flavors

Main features of the Vacuum Evaporator

- Vacuum processing: 0.1-0.3 bar absolute pressure for low-temperature boiling (40-70°C)

- Effective removal of air and dissolved gases: >95% reduction of oxygen

- Evaporation capacity: 1,000 to 15,000 kg of water/hour depending on configuration

- Final concentration: up to 50% dry matter depending on the product

- Constructed entirely of food-grade AISI 316L stainless steel

- Optimized energy consumption: 1.1-1.3 kg of steam per kg of water evaporated

- Thin-film dispensing system for uniform evaporation

- Integrated high-efficiency droplet separator

- Certifications : CE, FDA, EHEDG, 3-A Sanitary Standards

- PLC control with 15" touchscreen HMI interface and data logging

- Integrated CIP automatic cleaning system

Full description

Our vacuum milk evaporator represents excellence in dairy product concentration. Designed specifically to remove air and dissolved gases from milk, it combines efficient degassing with exceptional preservation of nutritional and organoleptic qualities.

The vacuum-falling film technology allows for gentle evaporation at low temperatures, preventing the denaturation of milk proteins and the degradation of heat-sensitive vitamins. The patented dispensing system transforms the product into a thin film that ensures optimal mass transfer and homogeneous evaporation.

Removing dissolved oxygen prevents oxidation, which is responsible for changes in color and taste, as well as the loss of nutritional value. This evaporator is particularly well-suited for dairies seeking to produce high-quality dairy concentrates for cheesemaking, powdered milk, or dairy ingredients.

Technical data of the Vacuum Evaporator

| Setting | Specifications |

|---|---|

| Machine type | Vacuum Falling Film Evaporator |

| Evaporation capacity | 1,000 - 15,000 kg water/hour |

| Operating pressure | 0.1 - 0.3 bar absolute |

| Evaporation temperature | 40-70°C (depending on product and concentration) |

| Concentration maximum | Up to 50% dry matter |

| Energy efficiency | 1.1 - 1.3 kg steam/kg water evaporated |

| Steam pressure required | 3 - 8 bar |

| Cooling water consumption | 10-50 m³/hour depending on capacity |

| Installed electrical power | 25-150 kW |

| Heat exchange surface | 50 - 500 m² depending on the model |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| Thin film dispensing system | Thermal steam compressor |

| Integrated droplet separator | MVR (Mechanical Vapor Recompression) system |

| Automatic CIP cleaning | Direct contact vapor condenser |

| Automatic level control | Online dry matter analyzer |

| 15" Touchscreen User Interface | Ethernet connection and monitoring |

| Recording of HACCP parameters | Calorie recovery system |

| Automatic control valve | Online dissolved oxygen sensor |

| Protection IP65 | Complete hygienic fairing |

FEATURES DETAILS

Patented thin-film dispensing system

Our distribution system transforms the milk into an extremely thin film that flows by gravity over the heating tubes. This technology ensures optimal mass transfer and homogeneous evaporation, preserving product quality while maximizing energy efficiency.

Advanced vacuum degassing

The vacuum-operated system effectively removes air and dissolved gases from the milk, preventing oxidation and changes in color and taste. This gas removal also improves the stability of the concentrated product and its rehydration properties.

Integrated energy recovery

The evaporator incorporates heat exchangers for energy recovery between the outgoing concentrated product and the incoming product, significantly reducing steam consumption and operating costs.

Areas of application

Our vacuum evaporator is suitable for various applications in the dairy industry:

- Condensed milk - For the production of unsweetened and sweetened condensed milk

- Pre-concentration for drying - Optimization of drying towers for powdered milk

- Concentrates for cheesemaking - Increased cheese yield

- Dairy ingredients - Concentration of milk proteins and whey

- Concentrated cream - For high-fat dairy products

Advantages of vacuum processing

Optimal nutritional preservation

Low-temperature vacuum evaporation preserves native proteins, heat-sensitive vitamins and aromatic compounds, ensuring a superior quality concentrated product.

Elimination of organoleptic defects

The removal of air and dissolved gases prevents oxidation which is responsible for cooked tastes and color changes, ensuring a final product with exceptional organoleptic qualities.

Energy efficiency

Vacuum technology combined with energy recovery systems allows for significant savings in operating costs compared to traditional evaporators.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.