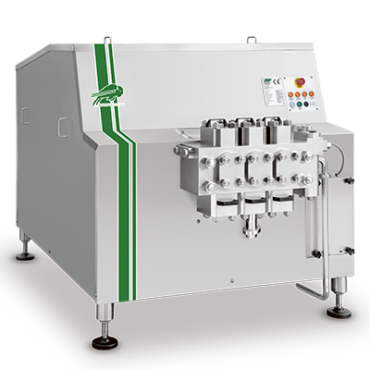

Bacteria Removal Centrifuge

Bacteria Removal Centrifuge

Advanced bactofugation technology for optimal microbiological purity

Our RE-B series centrifugal is specially designed for the efficient removal of spores and bacteria (bacteriofugation), while ensuring gentle milk processing, high separation efficiency and a wide flow capacity range.

Type: High-speed bacterial centrifugal

Application: ESL milk, milk powder, cheeses and dairy products

Advantage: Reduction of >95% of aerobic spores

Main features of the Bacterial Centrifuge

- Reduction of more than 80% in total bacterial load

- Elimination of over 95% of aerobic spores for optimal microbiological safety

- Reduction of more than 98% of anaerobic spores

- Processing capacity: 60 to 50,000 liters/hour depending on configuration

- Constructed entirely of food-grade AISI 316L stainless steel

- Dual operating system: two-phase and single-phase

- Automatic expulsion of solids for continuous operation

- Certifications: CE, FDA, EHEDG, 3-A Sanitary Standards

- PLC control with 15" touchscreen HMI interface and real-time monitoring

- Silent operation with advanced acoustic protection

Full description

Our RE-B series bacterial elimination centrifuge represents excellence in the microbiological purification of dairy products. Designed specifically for bactofugation, it combines rigorous removal of spores and bacteria with exceptional preservation of the product's organoleptic qualities.

High-speed centrifugation technology enables efficient separation without damaging the fat globules, thus preserving the natural structure of the milk. The dual-function system offers unique operational flexibility, allowing either maximum reduction of the bacterial load or recirculation to minimize product loss.

This centrifuge is particularly suitable for dairies seeking to improve the microbiological quality of their products, especially for the production of ESL milk, milk powder, cheeses and whey-derived products intended for infant food.

Technical Data of the Bacterial Centrifuge

| Setting | Specifications |

|---|---|

| Machine type | High-speed bacterial centrifuge |

| Processing capacity | 60 - 50,000 L/hour |

| Total bacteria reduction | > 80% |

| Aerobic spore reduction | > 95% |

| Anaerobic spore reduction | > 98% |

| Operating systems | Two-phase and single-phase |

| Rotation speed | Up to 8,500 rpm |

| Materials in contact | AISI 316L, EPDM, sanitary seals |

| Electricity consumption | 30-150 kW depending on capacity |

| Operating pressure | Up to 6 bar |

| Noise level | < 75 dB(A) |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| High-performance centrifugation bowl | Vibration monitoring system |

| Dual operating system | Online turbidity controller |

| Automatic expulsion of solids | SIP Automatic Washing System |

| Protection of fat globules | Real-time bacterial analyzer |

| 15" Touchscreen User Interface | Ethernet connection and remote monitoring |

| Recording of HACCP parameters | Complete traceability system |

| Acoustic fairing | Complete hygienic fairing |

| Easy integration with existing lines | Product recovery module |

FEATURES DETAILS

Innovative dual operating system

Our centrifuge offers two operating modes: the traditional two-phase system for maximum reduction of bacterial load, and the single-phase system with recirculation of the bacterial phase in the raw milk to minimize product loss. The operator can freely choose the system best suited to their needs.

Advanced protection of fat globules

The patented design of the centrifugation bowl ensures efficient separation without damaging the structure of the fat globules, thus preserving the natural qualities of the milk and avoiding any alteration of the emulsifying properties.

Automatic expulsion of solids

The automatic expulsion system allows for continuous, uninterrupted cleaning, optimizing productivity and reducing downtime. The expulsion frequency and duration are adjustable according to the product's bacterial load.

Areas of application

Our bacterial elimination centrifuge is suitable for various applications in the dairy industry:

- Fresh pasteurized milk - Microbiological quality improvement

- Long-life (UHT) milk - Prior elimination of resistant spores

- ESL (Extended Shelf Life) Milk - Ideal complement to heat treatment and pasteurization

- Milk powder - Reduction of microbial load before drying

- Cheeses and cheese products - Improving quality and preservation

- Whey derivatives - Whey proteins for infant formula

Advantages of bactofugation treatment

Exceptional microbiological quality

Eliminating heat-resistant spores and bacteria allows for levels of microbiological purity that are unattainable by heat treatments alone, which are essential for sensitive products such as infant food.

Lifespan extension

The significant reduction of the initial microbial load makes it possible to extend the shelf life of fresh products while maintaining their natural organoleptic qualities.

Flexibility and operational efficiency

Easy integration into existing processing lines and the two operating systems offer maximum adaptability to the specific needs of each production.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.